VMTech Co., Ltd.

| Exhibitor name |

VMTech Co., Ltd.

VMTech Co., Ltd.

|

|---|---|

| Booth NO. | 6A-321-8 |

| Address |

〒16-702 OVERSEAS(海外) "KyungHee Lespia Bldg 7F, 50, 6beon-gil, Youngil-ro, Yeongtong-gu, Suwon-si, Gyungki-do, KOREA" VMTech Co., Ltd. "KyungHee Lespia Bldg 7F, 50, 6beon-gil, Youngil-ro, Yeongtong-gu, Suwon-si, Gyungki-do, KOREA" |

| Website | www.vmtech.co.kr |

| PR message | Full 3D Injection Molding CAE SW (MAPS-3D) Real time Injection Molding CAE SW (MAPS-3D ez) - More than 90% accuracy compared to general CAE - 500~3000 times faster than injection molding CAE - Easy to use even for non-exports without mesh edit - Low-cost, high-efficiency CAE VM Material Lab |

| The Main Item |

|

| Movie |

|

| The name of Item[1] | Injection Molding Analysis SW (MAPS-3D, MAPS-3D ez) |

| Details[1] |

- Studio / Modeler / Material DB / CAD / File interface (CAD / Mesh) - MAPS-3D CIM (Flow/Cool/Pack/Warp) - Fiber/Flake/Magnetic orientation analysis - Insert analysis - Hot runner Manifold analysis / Hot Nozzle analysis - RIM analysis / Overmolding analysis / LIM-MCM - MAPS-3D Material Fitting P/G Real time Injection Molding CAE SW (MAPS-3D ez) - More than 90% accuracy compared to general CAE - 500~3000 times faster than injection molding CAE - Easy to use even for non-exports without mesh edit - Low-cost, high-efficiency CAE VM Material Lab - Polymer properties for CAE - Thermal properties(Tg, Tm, Teject) - Thermal conductivity - pvT - Viscosity |

| The name of Item[2] | VMTECH Company Introduction |

| Details[2] |

- Develop user friendly Injection molding CAE S/W - Analysis of the phenomena of the entire injection molding process in the mold - Design review of injection molding part and prediction of moldability and dimensional stability - Technical support through more than 30 years of experience VMTech Business - Development and sales of S/W - Application program development - CAE consulting - User demand program development - Material test service - Educational support |

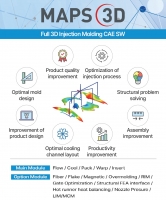

| The name of Item[3] | Full 3D injection molding CAE SW MAPS-3D |

| Details[3] |

MAPS-3D can analyze filling, packing, fiber orientation, cooling process, warping, etc. A factory with high product quality by optimizing injection conditions such as filling time, injection temperature, and mold clamping force, a product design with high assembly efficiency with less warping and twisting, and rapid and uniform cooling by designing an optimal cooling system. The system has the effect of reducing cycle times and significantly increasing productivity. You can discover various problems that occur during the molding process, such as short shots, weld lines, and gas pockets. You can also anticipate and find solutions to potential problems that may arise from product design to mold design. Powerful and easy operation in Japanese |

| The name of Item[4] | Real Time Injection Molding CAE SW MAPS-3Dez |

| Details[4] |

- Ultra-high speed flow solver (500 to 3000 times faster than current software) - Anyone can use it for work easily and conveniently - Low cost, high efficiency SW - More than 90% accuracy compared to standard CAE - Utilization of geometric shape information - No mesh modification required advantage - STL only - Super fast calculation speed - Low cost implementation costs - Real-time collaboration - Utilization of non-experts - No mesh modification required Application field - Thickness verification - Think mark - Shrinkage Review - runner balance - Gate design - projected area - Mold clamping force verification |

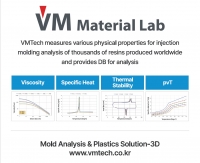

| The name of Item[5] | Material testing service VM Material Lab |

| Details[5] |

Thermal properties of polymer from DSC - Specific heat (Cp) - Glass transition temp. (Tg) - Melting temp. (Tm) - Ejection temp. (Teject) - Provide Processing windows - Degree of crystallization Testing items from RHEOGRAPH 50 - Thermal conductivity (k) - pvT (pressure-volume-temperature) - Viscosity (Balgey / Rabinowitsch correction) |

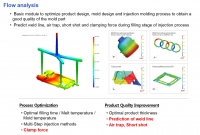

| The name of Item[6] | MAPS-3D Modules - Flow analysis |

| Details[6] |

3D filling process analysis inside the mold ● Influence of product wall thickness and dimensioning and optimization of gate and runner systems ● Prediction of short shots, weld lines, and gas pockets ● Optimization of injection conditions such as filling time, injection temperature, mold clamping force, etc. ● Preventing overpacking (excessive packing pressure) and underpacking (insufficient packing pressure) through balanced flow. |

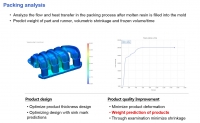

| The name of Item[7] | MAPS-3D Module - Packing analysis |

| Details[7] |

Analyzes three-dimensional flow and heat transfer phenomena while molten resin is contracted while cooling and solidifying through the packing process. ● Understanding volumetric shrinkage rate, density distribution, and resin solidification rate ● Injection molding machine size determination based on mold clamping force and injection amount evaluation ● Minimize uneven shrinkage that causes product warpage. ● Simulate the total weight of the entire product |

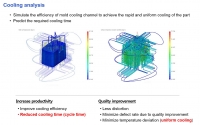

| The name of Item[8] | MAPS-3D Module - Cooling analysis |

| Details[8] |

Cooling process analysis of 3D injection molding ● Achieving rapid and uniform mold cooling through optimal cooling system design ● Reduced cycle time and improved product quality ● Uniform cooling reduces product residual stress and thermal stress. ● Reduced product distortion and improved product dimensional accuracy due to non-uniform cooling ● Reduce defective rate by improving surface quality |

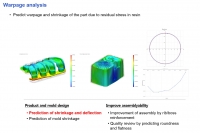

| The name of Item[9] | MAPS-3D Module - Warpage analysis |

| Details[9] |

Analysis of three-dimensional distortion and shrinkage phenomena after product removal due to residual stress generated within the resin while shrinking while cooling and solidifying. ● Consideration of dimensional stability when selecting molded product materials ● Application of appropriate mold shrinkage rate ● Distortion prediction during mass production, product design changes, and mold cooling structure optimization ● Improved ease of assembly by reinforcing ribs, bosses, etc. |

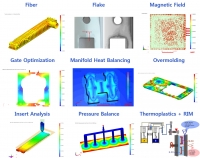

| The name of Item[10] | MAPS-3D Optional Modules |

| Details[10] |

Analysis of fiber orientation, anisotropy, and mechanical properties of resins to which glass fibers and carbon fibers are added to strengthen the mechanical strength of molded products. Overmolding Analyze the injection molding process when two different polymers are injected into one mold within an order Gate optimization Automatic prediction of optimal gate position with good charging balance RIM(Reactive Injection Molding) Analysis to predict various physical phenomena that occur after flow, holding pressure, and removal of thermosetting resin LIM/MCM The LIM/MCM process interprets the process of overmolding thermoplastic materials and liquid silicone (LSR). Hot Runner Heat Balancing/Nozzle Pressure Balance Analysis to predict the optimal position of the heater by thermal analysis of the hot runner manifold Nozzle Pressure Balance Analysis that can optimize the hot runner diameter by calculating the resin flow rate of the hot nozzle according to the nozzle position |

| Category of Exhibit Items |

L. CAD/CAM/CAE SYSTEM CAD/CAM/CAE System |