瑞穂工業株式会社

| Exhibitor name |

瑞穂工業株式会社

Mizuho Industries Co., Ltd

|

|---|---|

| Booth NO. | 6A-232 |

| Address |

〒555-0001 大阪府 大阪市西淀川区佃5丁目9-31 9-31, Tsukuda 5-chome, Nishiyodogawa-ku, Osaka-City, OSAKA, 555-0001 |

| Website | http://www.mizuho-loy.co.jp/ |

| Phone number | +81-6-6471-4721 |

| PR message | The surface treatment "SurmoX®" for our unique cemented carbide products can process small-diameter, deep inner diameters that conventional coatings cannot handle.For cutting tools with small diameters in cemented carbide, we have developed an ultrafine particle material called "KFX10". |

| The Main Item |

|

| Movie |

|

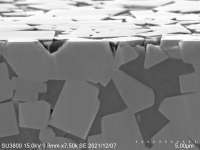

| The name of Item[1] | The SurmoX treatment |

| Details[1] |

(1)Capable of processing small-diameter, deep inner diameters. (2)No dimensional changes before and after treatment. (3)Applicable to products like shrink fitting and soldering. Additionally, here are confirmed cases demonstrating its effectiveness: (1)Cold forging dies experienced a significant increase in lifespan. (2)Improved release properties for powder metallurgy molds. (3)Halved the burr from cutting with a cemented carbide slitter. (4)Cemented carbide wire drawing dies doubled their lifespan. (5)Extended the lifespan of various cemented carbide guides. The treatment shows effectiveness in areas with high surface roughness. We offer proposals from cemented carbide material to finished products. It's also applicable to supplied items. Please feel free to inquire. |

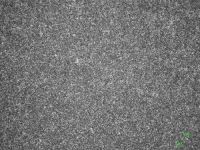

| The name of Item[2] | KFX10 |

| Details[2] |

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Materials Mold Components Formed Products Others D. CUTTING TOOLS Cemented Carbide Tools Cemented Carbide Tips F. SURFACE FINISHING, MODIFYING, WELDING Surface Finishing System N. PARTS PROCESSING TECHNOLOGY Cutting Processing Plasticity Processing |