株式会社 鈴木

| Exhibitor name |

株式会社 鈴木

SUZUKI CO.,LTD

|

|---|---|

| Booth NO. | 3-301-30 |

| Address |

〒382-8588 長野県 須坂市大字小河原 2150-1 2150-1 Ogawara, Suzaka Nagano Pref., 382-8588 Japan |

| Website | https://www.suzukinet.co.jp/ |

| Phone number | +81-26-251-2633 |

| PR message | Composite Die processing for assembling and welding different materials. A press terminal for battery that has been thickened and cold forged by a progressive press. Integrated production system of press → plating → molding → assembly. Support for the development of in-vehicle press-fit terminals. |

| The Main Item |

|

| The name of Item[1] | Precision press fit connector |

| Details[1] |

|

| The name of Item[2] | Precision rounding processing |

| Details[2] |

|

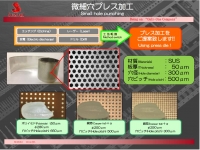

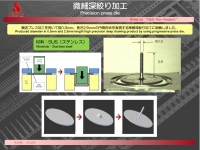

| The name of Item[3] | Small hole punching |

| Details[3] |

|

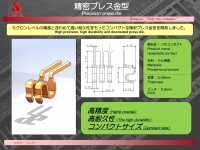

| The name of Item[4] | Precision press die |

| Details[4] |

|

| The name of Item[5] | Precision press die |

| Details[5] |

|

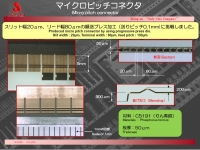

| The name of Item[6] | Micro pitch connector |

| Details[6] |

|

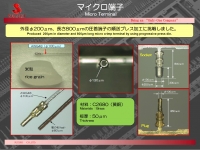

| The name of Item[7] | Micro Terminal |

| Details[7] |

|

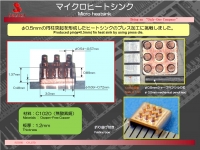

| The name of Item[8] | Micro heatsink |

| Details[8] |

|

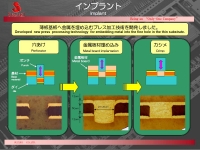

| The name of Item[9] | Implant |

| Details[9] |

|

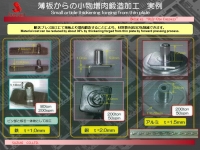

| The name of Item[10] | Small article thickening forging from thin plate |

| Details[10] |

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds N. PARTS PROCESSING TECHNOLOGY Precision Processing |