The Japan Metal Stamping Association proudly annouce their memebers showcase formed samples and products at Japan Metal Stamping Technology Exhibition 2013.

These are receiving plenty of attention from various manufacturers related to electrical automobiles, digital mobile devices, and the latest products.

We look forward to seeing you at the show!

We can propose to reduce by automatic caulking and comply with your requests from trial to mass production.

| Address | 3122 Ago kasama-shi, Ibaraki-ken, Japan | TEL FAX |

+81-29-945-7155 +81-29-945-7157 |

|---|---|---|---|

| HP | http://www.hskcoltd.co.jp | ||

| Division | Sales Section | Contact person | MARIKO OHNO |

| Exhibit Items |

|

||

Our company in foundation 1962 has practiced the about five decades and technical accumulation of press processing.

I am developing positive VE proposal from the product conceptual phase in recent years for a visitor's improvement in competitive power.

Global order-received / proposal activities are developed, and it is exerted for the improvement in visitor satisfactory also at our (Indonesia) factory which is the June, this year operation schedule.

| Address | 2770 MAENO, IWATA –CITY, SHIZUOKA-PREF. 438-0068 JAPAN | TEL FAX |

+81-538-35-6617 +81-538-37-0892 |

|---|---|---|---|

| HP | http://www.marutake-b.com | ||

| Division | Engineering Department Technical business Section | Contact person | Yoshiaki Yamashita |

| Exhibit Items |

|

||

Our fan is used in the wide field of an equipment of a house apparatus, an air conditioner, medical equipment, the industrial instrument.

| Address | 3-10-7 HIGASHIKOJIYA, OHTA-KU, TOKYO, JAPAN | TEL FAX |

+81-3-3742-0221 +81-3-3741-1406 |

|---|---|---|---|

| HP | http://www.rokugo.co.jp | ||

| Division | Sales Department | Contact person | JUN KAMIYAMA |

| Exhibit Items |

|

||

We have developed and refined on "steel plate ColdForging" and "Extra Precise Blanking". We have also succeeded in cutting fundamental production cost to abolish medium process such as annealing and bonding.

| Address | 1414 Shimonomoto,Higashimatsuyama,Saitama 3550036 JAPAN | TEL FAX |

+81-493-23-1213 +81-493-23-1216 |

|---|---|---|---|

| HP | http://www.toshima-mfg.jp/ | ||

| Division | Parts Division Sales Dept | Contact person | Satoru oe |

| Exhibit Items |

|

||

Integrated manufacturing system The integrated manufacturing system from development, stamping, welding assembly, to painting process has been implemented.

Cost Competitiveness The cost competitive manufacturing capability at Heian Manufacturing replaces die-casting or sintering with the sheet metal.

Weight Reduction Technology Heian offers the state of the art weight reduction technology by combining Board Forging Method around critical strength areas and minimizing the sheet thickness in the other areas.

| Address | 464 Nakasho Makino-Cho Takashima,Shiga,520-1823 JAPAN | TEL FAX |

+81-740-27-2161 +81-740-27-1277 |

|---|---|---|---|

| HP | http://www.heian-mfg.co.jp/ | ||

| Division | Development sales department | Contact person | Yoshinobu Obata |

| Exhibit Items |

|

||

Recently, complicated shape, low cost, improvement of the forming technology to keep environmental consideration becomes the main needs of the automobile industry, and similar directionality is demanded to the technology development of the metal press working industry which is the prime partner. We aim to develop plastic deformation processes in this directionality.

| Address | 118 IDA,KITASAKI-MACHI,OBU-SHI,AICHI,JAPAN | TEL FAX |

+81-562-47-5126 +81-562-47-5127 |

|---|---|---|---|

| HP | http://www.fuji-press.co.jp/ | ||

| Division | Technology Department | Contact person | KANIE Toshiya |

| Exhibit Items |

|

||

We are specialist of MULTI-FORMING. The material is a stainless, iron, copper, and aluminum, etc. It was involved in this for 50years or more, there are results in various fields. And, it has a state-of-the-art technology. If the drawing where shape is submitted, it estimates. Of course, it is free. Please feel free to give to me of the report. We will wait.

| Address | 1-23-2 KANAMACHI KATSUSHIKA-KU TOKYO Japan 125-0042 | TEL FAX |

+81-3-3608-2735 +81-3-3608-7035 |

|---|---|---|---|

| HP | http://www.forming.jp | ||

| Division | Sales Department | Contact person | Takashi Sato |

| Exhibit Items |

|

||

| Address | 2-4-32 KitaShinbo Sanjo-city, Niigata ,Japan | TEL FAX |

+81-256-33-0551 +81-256-34-7261 |

|---|---|---|---|

| HP | http://www.aiei-sangyo.co.jp/ | ||

| Division | Contact person | Kazumi Watanabe | |

| Exhibit Items | |||

Our company was founded in 1999 under the certification of "Riken venture system" in order to spread and achieve the practical use of research results of the Institute of Physical and Chemical Research.

Under the circumstance of the drastic advances in technical innovations development recently, we are helping our valued customers with solving their complications by providing solutions including items, consulting, and technological development arising from the combination of IT technologies based on the science and the Japanese proprietary know-how.

| Address | 2-3-13, Minami, Wako, Saitama, 351-0104, Japan | TEL FAX |

+81-48-450-1351 +81-48-450-1350 |

|---|---|---|---|

| HP | http://www.astom.co.jp | ||

| Division | Business/plan operation division | Contact person | Masato tsutsumi |

| Exhibit Items |

|

||

| Address | 300 Tsubuta Kita Minamiushiroya,Yashio City 340-0831 Saitama Pref. Japan | TEL FAX |

+81-48-931-4172 +81-48-935-5063 |

|---|---|---|---|

| HP | http://www.skk-sugawa.co.jp | ||

| Division | Sales department | Contact person | zanma yuuji |

| Exhibit Items | |||

| Address | Wako RIKEN Incubation Plaza, 2-3-13 Minami, Wako-shi, Saitama-ken, Japan | TEL FAX |

+81-48-469-8311 +81-48-486-9367 |

|---|---|---|---|

| HP | http://www.nexsys.co.jp | ||

| Division | sales department | Contact person | Kiyoshi Kubo |

| Exhibit Items |

|

||

We will meet any of your needs when it comes to press die, made by the latest machine tool, manufacturing equipment, micro-fabrication, and injection mold for medical field and the automobile industry.

Furthermore, we can design and make test production by your custom-tailoring.

In addition, we provide support depending on your request; product supply, production by commissioning and dispatch of engineers.

| Address | 93 Yokomichi, Hirakawa, Joyo-shi, Kyoto 610-0101 | TEL FAX |

+81-774-55-8500 +81-774-53-7873 |

|---|---|---|---|

| HP | http://www.yamaoka.co.jp | ||

| Division | Sales Department | Contact person | Akifumi Orito |

| Exhibit Items |

|

||

The stamping industry has been required to respond to some changes such as high-mix low volume production and low prices since the age of mass production. To address the situation, we developed a take-out machine that increases production efficiency of high demand compound processing. This take-out machine prevents pinch point accidents and improves the quality of products. It is in demand overseas and has expanded your business globally.

| Address | 1-15-14, Shimotoda, Toda-shi, Saitama, 335-0011, Japan | TEL FAX |

+81-48-442-1620 +81-48-443-5520 |

|---|---|---|---|

| HP | http://mikumo.biz | ||

| Division | sales promotion | Contact person | Hayato Yamauchi |

| Exhibit Items |

|

||

We product high precision parts of automatic transmission

We can product micro hole whose size is 50% of the plate thick. The both side of the Hole with chamfer or round chamfer is possible using progressive machine

We develop high precision parts and long life punches

| Address | 48 Fukami Kamikayazu Ama City Aichi Pref Japan 490-1112 | TEL FAX |

+81-52-441-7771 +81-52-441-7776 |

|---|---|---|---|

| HP | http://www.sato-ind.co.jp | ||

| Division | TECHNICAL PLAN DEPT | Contact person | Kiichiro Nagahata |

| Exhibit Items |

|

||

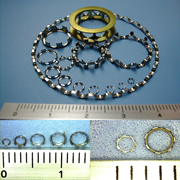

Consistent service from designing, mold building to metal press working, resin injection molding, we offer you product tailored to your specification and use application.

Taking advantage of acquired technique of building mold for bearing retainers which requires accuracy, we specialize in precision working,.

Prices negotiable by overseas production.

| Address | 1-3-1 Shinmei Kugenuma Fujisawa city, Kanagawa prefecture, JAPAN 251-0021 | TEL FAX |

+81-46-627-6201 +81-46-622-4952 |

|---|---|---|---|

| HP | http://www.tki.ne.jp/~public/japan/top_j.html | ||

| Division | Sales Department | Contact person | Ryuta Matsubayashi |

| Exhibit Items |

|

||

| Address | 1417-10 Kanaoricho,Minami-ku,Hamamatsu,Shizuoka 435-0026,Japan | TEL FAX |

+81-53-425-2511 +81-53-425-4425 |

|---|---|---|---|

| HP | http://www.kyoei-seisaku.co.jp | ||

| Division | sales division sales group | Contact person | Hayato Fujita |

| Exhibit Items | |||

We manufacture car parts by cold-forging, stamping, drawing, bending, etc.

Main showpiecies are as follows.

/Cold forged parts made of SUS304 and SUS440C

/Cold-forged fuel injection parts without burrs inside

/Deep-drawing Cover Integrated with pipe

/Stamping parts with differential thickness

| Address | 16-1 Kanayama Aizuma-cho Chiryuu-shi Aichi JAPAN | TEL FAX |

+81-566-83-8305 +81-566-83-0236 |

|---|---|---|---|

| HP | http://www.miyama-grp.co.jp/ | ||

| Division | Sales Department | Contact person | Tatsuya Yamamoto |

| Exhibit Items |

|

||

SOODE NAGANO displays the samples of our core technology; Precision Stamping and Cold Forging Stamping. Those parts are used for HDD (Hard Disk Drive), Camera, Case, Heat Sink and more. We can also combine with secondary processes like machining , grinding, or plastic molding to satisfy customer's needs and spec.

Knowledge ,Experience by production for the several industries are now applied for New Technologies such as Lithium – Ion Battery Industry production.

| Address | 2-5-21 KATAMA-CHO OSACHI OKAYA-CITY NAGANO-PREF.,394-0084 JAPAN | TEL FAX |

+81-266-263500 +81-266-263511 |

|---|---|---|---|

| HP | http://www.soode.co.jp/ | ||

| Division | Sales section | Contact person | Ichiro Yamada |

| Exhibit Items |

|

||

Xerom provides small parts areas including electronic parts, medical parts, Li-ion batteries, car electronics and environmental industries.

| Address | Osaka Anix Building 5th Floor 1-14-20 Itachibori, Nishiku, Osaka City | TEL FAX |

+81-6-6578-4588 +81-6-6578-4580 |

|---|---|---|---|

| HP | http://www.xerom.jp | ||

| Division | Sales Department | Contact person | Yasunori Shimoji |

| Exhibit Items |

|

||

ASTEER is global supplier who continues to challenging for evolution and creation in order to be automotive part manufacturer contributing for realization of more comfortable motorized society.

We have our eyes set on being a company who can win reliability and sympathy from carmakers in the world as "value-creating and proposal-based company" focusing patented products and increasing development ability and competitiveness.

| Address | 1597, Makabe, Soja, Okayama 719-1134 | TEL FAX |

+81-866-93-2321 +81-866-93-0415 |

|---|---|---|---|

| HP | http://www.asteer.co.jp/ | ||

| Division | Sales/Marketing Section II | Contact person | HIROYUKI YAMADA |

| Exhibit Items |

|

||