The members of the Japan Die & Mold Industry Association proudly showcase molds and formed samples for a new generation of vehicles, medical devices, and to other leading industries at INTERMOLD 2013. These technologies are receiving plenty of attention. The domestic demand is increasing year by year.

We look forward to seeing you at the show!

It is adopted as a development-types company at the sponsored research development period of the country, and is progressing toward the further research and development.

| Address | 3-38 Takasago, Takaishi, Osaka Prefecture 592-0001 | Telephone Facsimile |

+81-(0)72-268-1006 +81-(0)72-268-1007 |

|---|---|---|---|

| HP | http://www.nodakanagata.co.jp/ | ||

| Division | CAM Room | Contact person | Masahiro Ishida |

| Exhibit Items |

|

||

We have developed widely our independent technical method, these Inner Slide systems method (Collapsible core), pulling up as per Rotation Style.

1.TO BE eliminated second process work

2.TO BE become ONE part from TWO different parts.

3.TO BE decreased rework times will be making by super high precision process.

AS an above, We would like to submit you our proposal.

| Address | 6-7-7, Kouhoku Adachi-ku Tokyo 123-0872,Japan | Telephone Facsimile |

+81-3-3856-0505 +81-3-3856-2777 |

|---|---|---|---|

| HP | http://www.shoujoh.co.jp | ||

| Division | Contact person | RYO MAEJIMA | |

| Exhibit Items |

|

||

Our global performance on plastic injection moulds can bring you an improvement of productivity setting. We have kept providing unusual moulds by fusing Japan with Vietnam since 2003.

And we are starting operation of Indonesia plants in 2012 Dec. That will bring you more convenient and profitable service in world wide.

Let's explore "good price, good work", which is prepared by "NSK global factory" collaboration together.

| Address | 66-5 Kitatsurune Ogawa,Higashiura-Cho,Chita-Gun Aichi,Japan | Telephone Facsimile |

+81-562-84-7600 +81-562-84-7644 |

|---|---|---|---|

| HP | http://www.nagoya-sk.co.jp | ||

| Division | Sales Dept | Contact person | Tadashi Furuhashi |

| Exhibit Items |

|

||

We mainly plate molds with hard chrome.

We can plate molds of complicated shape and adjust mold's dimention.

In addition ,we also treat hardened molds and those of nitriding.

| Address | 1-25-4 Nakarokugo Otaku Tokyo | Telephone Facsimile |

+81-33-734-4561 +81-33-732-8191 |

|---|---|---|---|

| HP | http://www1.cts.ne.jp/~nitto/ | ||

| Division | sales division | Contact person | Takashi Koyama |

| Exhibit Items |

|

||

| Address | Telephone Facsimile |

+81-76-352-1427 +81-76-352-6139 |

|

|---|---|---|---|

| HP | http://www.hizima.co.jp/ | ||

| Division | Contact person | ||

| Exhibit Items | |||

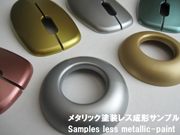

We are the designer and manufacturer of injection molds. Backed by vast experiences in industries like automotive, home appliances, office automation and musical instruments, we offer high expertise, flexible operation system, and service tailored to the customer's needs mainly in the field of mold technology. Our company also has been taking an active approach in technological development in recent years. The "metallic color paint-free molding technology" and The "super thin thickness aluminum die-casting technology", exhibited at INTERMOLD 2012, is drawing keen attention as an economical and green technology. UCHIYAMA SEIKO's superior technology will support your sound production activities.

| Address | 639 SAGISAKAKAMI IWATA-CITY SHIZUOKA 438-0005 | Telephone Facsimile |

+81-538-461 +81-538-4612 |

|---|---|---|---|

| HP | http://www.uchiyama-seiko.co.jp/ | ||

| Division | PRESIDENT | Contact person | Hirotatsu Uchiyama |

| Exhibit Items |

|

||

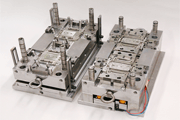

Ever since we were founded in 1967, we have been satisfying customers' needs in a specific manner by pursuing precise plastic mold manufacturing.

Our company is characterized by mold manufacturing, which combines new technologies with the traditional ones, integrating expert skills that have been cultivated from years of experience, as well as continuously updating to the latest equipment.

With absolute "quality", "speed", and "a global perspective" as our keywords, we will try new territories and manufacture goods with the world in sight, aiming to become a company that our customers can trust as a business partner.

| Address | 651-1 Nishi-shingai,Shimoshidami, Moriyama-ku, Nagoya City, Aichi Pref, Japan 463-0003 | Telephone Facsimile |

+81-052-736-0661 +81-052-736-0663 |

|---|---|---|---|

| HP | http://www.tnk-mold.com | ||

| Division | Manufacture department | Contact person | Koyama Youichi |

| Exhibit Items |

|

||

3次元のソリッド・CAEからの高精度金型製作と成形部品の提供

あらゆる分野のニーズに応える生産技術

カメラ・ビデオ等光学機器、携帯電話、医療用機器、OA事務用機器、情報通信機器、自動車部品、異材質成形

設計・製造からトライ、寸法測定までトータルな品質管理

光学素子用金型のナノレベル加工

中国深セン市、無錫市に成形機80台。塗装・印刷・金型メンテナンス

| Address | 〒211-0012 神奈川県川崎市中原区中丸子57 |

Telephone Facsimile |

044-433-8371 044-433-8374 |

|---|---|---|---|

| HP | http://www.nagatsu.co.jp/ | ||

| Division | 営業技術部 | Contact person | 川島 光隆 |

| Exhibit Items |

|

||

Ikegami is committed to providing our customers with state-of-the-art molds and components using both know-how that we have accumulated over our long history as a manufacture of plastic injection molds and leading-edge technologies in our endeavor to contribute to enhancing productivity and quality.

We can offer you the best solution for your successful products.

| Address | 2-664-8 TOYONODAI,KAZO, SAITAMA, 349-1148 JAPAN | Telephone Facsimile |

+81-480-44-8686 +81-480-72-8160 |

|---|---|---|---|

| HP | http://www.ikegami-mold.co.jp/ | ||

| Division | Reserch & Development Sec | Contact person | Makoto Otomo |

| Exhibit Items |

|

||

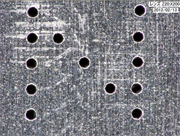

Originating from die manufacturing, OGAKI SEIKO CO., LTD (OSK) diversified into high precision stamping Today, with extensive know-how, OSK has a crucial role to supply HDD part which only four companies can produce world wide.

OSK specialized in designing and building precision progressive metal stamping dies and supplies those dies world wide.

Those die have contributed a great deal to the mass production of parts which Japanese companies have the top market share in the world.

| Address | 3-92-1 ASANISHI OGAKI-CITY GIFU-PREFECTURE | Telephone Facsimile |

+81-584-89-5811 +81-584-89-5545 |

|---|---|---|---|

| HP | http://www.ogakiseiko.co.jp | ||

| Division | BISINESS SECTION | Contact person | YUKIHIKO MORIGUCHI |

| Exhibit Items |

|

||

| Address | 2-15-5,NAKAIKEGAMI,OTA-KU,TOKYO 146-0081 JAPAN | Telephone Facsimile |

+81-33-755-5511 +81-33-753-1079 |

|---|---|---|---|

| HP | http://www.nishimura-ss.com/ | ||

| Division | Sales Dept | Contact person | Toshihiko Mitsui |

| Exhibit Items | |||

Since the company's founding in 1974, we have largely been manufacturers of screw caps but now we are relied upon for the design and manufacture of metal molds used for cosmetics, food, detergent, stationery ,medical products and daily necessities. Our company always strives to make metal molds with excellent durability and, at the same time, our biggest goal is to improve our technology to make excellent metal molds that can be adjusted at the micro level.

We, Matsuno, aim to become a "best solution partner" by using IT strategy which is based on the plant LAN system connected to Osaka, Kanto and Kyushu 3 factories. (called "MATSUNO style") For the fusion of process and sales control, flow analysis system, TV conference, we will meet the needs of times "speed" and "transparency". And we can supply reliable service with confidence.

| Address | 4-10, Shinjo-Higashi, Higashi Osaka City, Osaka, Japan 578-0951 | Telephone Facsimile |

06-6746-2717 06-6746-2846 |

|---|---|---|---|

| HP | http://www.matsuno-k.co.jp | ||

| Division | Sales Department | Contact person | Ota Hiroshige |

| Exhibit Items |

|

||

Since the foundation of the company, our core technology is the hand rapping to polish the metal surface to produce a super fine mirror finish.

Using a metal press machine such as FB-800t and UL-400t for the trial run, we are supplying ready to run, highly quality dies to those industries such as medical, automotive, food container, battery and turbine for power generation.

We have our own die manufacturing plant in Thailand, and also a business tie-up with Japanese die maker in China to cooperate our customers for their overseas operations.

| Address | 1-4-2,FUKUURA,KANAZAWA-KU,YOKOHAMA,JAPAN | Telephone Facsimile |

+81-45-785-1111 +81-45-785-4488 |

|---|---|---|---|

| HP | http://www.showa-seiko.co.jp | ||

| Division | Sales Department | Contact person | Mitsuru Dohi |

| Exhibit Items |

|

||

| Address | 1-357, MINAMISHINKAI_CHO, TSUSHIMA_CITY, AICHI 496-0072 | Telephone Facsimile |

+81-56-724-8787 +81-56-724-1288 |

|---|---|---|---|

| HP | http://www.shippo-mold.co.jp | ||

| Division | Manufacturing department | Contact person | HISANAGA TSUDA |

| Exhibit Items | |||

Isn't there any troubled matter -- that cost does not decline and with the product of machining, it cannot respond to production increase?

I realize form of machining and the level, and accuracy of dimension by the press processing of our company.

Please consult.

| Address | 175, Tai, Hokuei-cho, Touhaku-gun, Tottori, Japan 689-2103 | Telephone Facsimile |

+81-858-36-4311 +81-858-36-4651 |

|---|---|---|---|

| HP | http://www.terakata.jp | ||

| Division | Sales promotion division | Contact person | Yasuhiro Yagi |

| Exhibit Items |

|

||

We have been involved in mold parts processing for half a century. As parts processing Specialist, Progressive die, Sintering mold,Drawing die,we believe our mission is to deliver the accurate and reliable parts not only just for now but also for 5 years or 10 years ahead.Please contact us! We are working with great enthusiasm.

| Address | 2-17-15 Chuorinkan-nishi Yamato-city Kanagawa-pref.JAPAN | Telephone Facsimile |

+81-46-274-5482 +81-46-274-5477 |

|---|---|---|---|

| HP | http://www.mifuji.com | ||

| Division | BUSINESS DEPT | Contact person | Naoto Imai |

| Exhibit Items |

|

||

Half of domestic electricity consumption is motor.We use motor regardless of big things and small things. We will suggest the motor improvement.

| Address | 239 Shimohirama, Saiwai-ku, Kawasaki, Kanagawa, 212-8560 Japan | Telephone Facsimile |

+81-44-555-3924 +81-44-555-3522 |

|---|---|---|---|

| HP | http://www.kuroda-precision.co.jp | ||

| Division | Tool & Die dept | Contact person | Shuji Yoda |

| Exhibit Items |

|

||

We succeeded to improve acceleration of first cut process speed and cut down consumable of W-EDM,EDM at the same time.

In particularly, our proposal will be able to reduce using wire quantity with process thin work(about 5mm) from one fifth to one tenth.

Regarding to first cut speed, we realized to accelerate it 1.5 times without breaking wire.

| Address | Shimoze33 Fuchuu-Machi Toyama Japan | Telephone Facsimile |

+81-76-469-1501 +81-76-469-1551 |

|---|---|---|---|

| HP | http://www.mizusumasi.co.jp | ||

| Division | CEO | Contact person | Naoyuki Hashimoto |

| Exhibit Items |

|

||

Our company established in 1946 at TOYAMA, it is the first mold maker.

The based technological skill accumulation a long and have won a high of trust.

Also, use of Large 5 axis machining and CAE(flow analysis)support to Customer needs.

| Address | 118-1 Kitatakagi Imizu-City Toyama 939-0281 JAPAN | Telephone Facsimile |

+81-766-52-5222 +81-766-52-5223 |

|---|---|---|---|

| HP | http://www.uogishi.co.jp | ||

| Division | Contact person | Tsutomu UOGISHI | |

| Exhibit Items |

|

||

We started to develop precision products in 1985 and have designed/fabricated molds for small sized precious plastic parts to shift into full swing since 1992 to make responsive the changes of the times. At globalization eras, we brush up our know-how which we have accumulated reliability and technology; and conveys our creativity to the world.

| Address | 410-2 2CHOME NISHIKAIHOTU FUKUI-SHI FUKUI | Telephone Facsimile |

+81-77-653-3061 +81-77-653-1296 |

|---|---|---|---|

| HP | http://www.yoshinaka-seiko.co.jp/ | ||

| Division | General affairs | Contact person | Mariko yoshinaka |

| Exhibit Items |

|

||

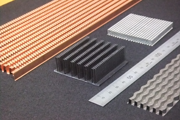

Our main business is to design / manufacture progressive precision dies and high speed and precision metal stampings. Our products support diverse requirements of various fields such as lighter,thinner,shorter,smaller,higherprecision,higher durability and a cost reduction.

In recent years,we are struggling to develop an inner fin for heat exchangers and an increase in efficiency and productivity.

| Address | 4-15-28 Onna,Atsugi-shi,Kanagawa,Japan 243-0032 | Telephone Facsimile |

+81-46-247-8693 +81-46-247-5960 |

|---|---|---|---|

| HP | http://www.kakio.co.jp | ||

| Division | Contact person | Yoshinobu homma | |

| Exhibit Items |

|

||

Ito Seisakusho Company Limited has an extensive experience with regards to the field of progressive die making.

Introducing the latest and high level equipment is our company's positive idea towards advanced manufacturing.

Our company is also engaged in metal press production. We sustain highest productivity using our own production system. Making us one of the leading metal press manufacturers in Japan.

| Address | 101 Hironaga cho, Yokkaichi, Mie, Japan zip 512-8061 | Telephone Facsimile |

+81-59-364-7111 +81-59-364-6410 |

|---|---|---|---|

| HP | http://www.itoseisakusho.co.jp/ | ||

| Division | Sales and Maruketing | Contact person | Tsuyoshi Kawasaki |

| Exhibit Items |

|

||

Our company specializes in mold parts for high precision optical lens and ultra precision micro pins.

As our main products

/Ultra precision lathe products

/Ultra precision cylindrical profile product.

We have developed our following technologies in the research and development of business and collaboration between industry, academia and government

/High accurate all grinding process without EDM process, Direct grinding for Glass Lens,

The Capsule Endoscope, Pain less micro needles.

| Address | 1445 Mushozu,Onga-cho,Onga-gun Fukuoka 811-4321 Japan | Telephone Facsimile |

+81-093-291-1778 +81-093-291-2728 |

|---|---|---|---|

| HP | http://www.wks-co.com | ||

| Division | Corporate Planning Division | Contact person | Yoshihide Nishio |

| Exhibit Items |

|

||

| Address | 2-6-9 miyauchi nakahara-ku kawasaki-shi | Telephone Facsimile |

+81-44-777-6744 +81-44-755-3183 |

|---|---|---|---|

| HP | http://www.moltec.co.jp/ | ||

| Division | Contact person | Koichi Matsui | |

| Exhibit Items | |||

We have experienced design and manufacture of injection dies for many years. With accelerated move to manufacture overseas in recent years, Muto achieved the same high levels of quality at head office in Tokyo, Shinjo plant in Yamagata, Kunshan plant in China and Korea. Overseas manufacturing bases make cost saving and ensuring of earlier delivery date for device (unit) order possible.

| Address | 4-16, Edogawa, Edogawa-ku, Tokyo 134-0013, JAPAN | Telephone Facsimile |

+81-3-3656-8651 +81-3-3656-8647 |

|---|---|---|---|

| HP | http://www.muto-mold.com/ | ||

| Division | Sales Department | Contact person | Hidenori Kawahara |

| Exhibit Items |

|

||

Our company have been producing die for die casting and gravity die casting, die parts and machine parts. We have strengthened the design, manufacturing, and the quality assurance system with the integration of digital technology and craftsmanship and we will solve any challenge for die production and machine part production. We offer the service of the design with 3D cad system(CATIA V5) to the automotive customers.

| Address | 1-8-15, Takaokanishi , Naka-ku, Hamamatsu-city, Shizuoka, 433-8118 | Telephone Facsimile |

+81-53-437-5691 +81-53-437-7085 |

|---|---|---|---|

| HP | http://www.bentom.co.jp/ | ||

| Division | Sales Dept | Contact person | Daisuke Honda |

| Exhibit Items |

|

||

Manufacture and sales of Plastic Mold, Hot Runner system and Ionizer.

We are specialists in plastic injection molding industry: hot runner systems and mold making/maintenance.

| Address | 7-12-11 Ikegami Ota-ku Tokyo Japan | Telephone Facsimile |

+81-3-3754-0661 +81+3-3754-0011 |

|---|---|---|---|

| HP | http://www.fisa.co.jp | ||

| Division | Contact person | Susumu Saito | |

| Exhibit Items |

|

||

Fine Tech Co. is the challenging company to produce the ultra-precision and minute-parts and molds using 160×103³rpm high speed precision milling machine and on machine-measuring ultra-precision turning machine, which are developed by our selves.

Please ask us to produce the precision products which are rejected by other producers.

| Address | 4-9-7 Higashi-Kojiya Ota-ku Tokyo 144-0033 Japan | Telephone Facsimile |

+81-3-5735-0888 +81-3-5735-0889 |

|---|---|---|---|

| HP | http://www.fine-tech.co.jp | ||

| Division | Precision Machinery & Parts Dept. | Contact person | Eiji Hatada |

| Exhibit Items |

|

||

Nagara is engaged in the design and manufacture of transport equipment in the press mold and press only towards consumer electronics, automotive, prototyping and production of molded parts flame plank. Through the press mold, proposed a Speedy low cost of manufacturing.

| Address | 1-21 Komotohonmachi ,Nakagawa-ku,Nagoya,Aichi-ken | Telephone Facsimile |

+81-52-362-6066 +81-52-362-2232 |

|---|---|---|---|

| HP | http://nagara.gr.jp | ||

| Division | Executive director | Contact person | Takashi Hayase |

| Exhibit Items |

|

||

'Suppon' enables you to form smartly 'impossible' undercut configurations.

'Suppon' can;

/set you free of restricted mold design that the conventional undercut molding mechanism has involved so far.

/reduce your mold die machining much more than ever thanks to 'Suppon' making your die simple and smaller.

/cut back the injection cost resulting from employing a smaller injection machine in which your smaller 'Suppon' mold die is set.

/make your undercut molding mechanism simple by the gimmick 'Suppon' has.

/make your undercut molding mechanism more reliable thanks to the high precision of 'Suppon', that is a complete factory-assembled unit in which all the parts you've machined, assembled and adjusted at site so far are packed in one unit.

Please visit our booth and check smoothly the 'Suppon' works!

| Address | 1-5-5 Matobacho, Minami-ku, Hiroshima, JAPAN 732-0824 | Telephone Facsimile |

+81-82-264-1010 +81-82-264-1071 |

|---|---|---|---|

| HP | http://www.technocrats.co.jp | ||

| Division | System Development Department | Contact person | Daisuke Nishimoto |

| Exhibit Items |

|

||

If you need to design a gear mechanism or a client has asked you to manufacture a gear, our staff will provide you with all the tools you need. Chiba Dies will offer you customized support services going beyond the mold to follow up with everything from profile design to materials, prototypes, mold creation, production, testing and research.

For example, we can respond to our customer's needs to:

/Eliminate noise

/Improve durability

/Switch from metal to plastic

/Improve precision

/Get advice, starting at the design stage

| Address | Osone414,Yashio-shi,Saitama340-0834,JAPAN | Telephone Facsimile |

+81-48-997-6621 +81-48-997-6625 |

|---|---|---|---|

| HP | http://www.chibadies.co.jp | ||

| Division | Sales Dept | Contact person | Shingo Uehara |

| Exhibit Items |

|

||

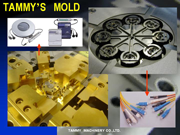

In recently years, our website has attracted new clients seeking companies with excellent mold manufacturing skills and capable of prototype production and mass-production of injection molded components. We have developed many plastic, ceramic and metal injection molded components for clients. Particularly, we excel in a support of the development of the medical devices.

| Address | 8-3-6, Fukaya-Naka, Ayase-city, Kanagawa, Japan | Telephone Facsimile |

+81-467-79-7301 +81-467-79-7602 |

|---|---|---|---|

| HP | http://www.tammy.jp | ||

| Division | Development Division | Contact person | Kuniharu Yamamoto |

| Exhibit Items |

|

||

| Address | 3-2-29 Jinmachi-Nishi,Higashine-shi,Yamagata,Japan | Telephone Facsimile |

+81-237-47-2555 +81-237-47-1674 |

|---|---|---|---|

| HP | http://www.daiseiken.co.jp | ||

| Division | Sales Dept | Contact person | Yuji Kumazawa |

| Exhibit Items |

|

||

Sansyu focuses in "Precision" on different areas of the injection molding field, especially in overmolding, thin-wall injection molding and ultra-small injection molding.

With production centers in Hong Kong, Indonesia and the U.S.A., Sansyu delivers precision parts around the world, aiming at becoming a truly global company.

| Address | 4-1-55, HIEDA-CHO, TAKAHAMA-CITY, AICHI, 444-1321 JAPAN | Telephone Facsimile |

+81-566-52-3421 +81-566-52-3311 |

|---|---|---|---|

| HP | http://www.sansyu.co.jp/ | ||

| Division | sales department | Contact person | TOMITA YOSHIKAZU |

| Exhibit Items |

|

||

SYVEC developed " CFP method " that combined cold forging with metal forming. We can form 3-D components by using it. Therefore, customers can switch the conventional methods such as the cutting and the sintering to press to reduce the cost and production times.

The metal separators for Fuel Cell and the cycloid reduction gear for EV are exhibited in INTERMOLD.

| Address | 1000-15 Goubara Minamihara, Hirooka, Shiojiri-shi, Nagano-ken 3990704 JAPAN | Telephone Facsimile |

+81-263-51-1869 +81-263-51-1815 |

|---|---|---|---|

| HP | http://www.syvec.co.jp | ||

| Division | Institute of Vaiue Technolog | Contact person | Masataka Hirabayashi |

| Exhibit Items |

|

||

Canon Mold is a specialized manufacturer of metal molds used in the making of an enormous range of products for various makers' products such as Automobiles, Medical devices, Food containers, Camera parts, Office equipments and Media case. We produce outstanding molds acclaimed for their superior precision, durability and productivities.

We will serve and contribute to the world's industry wholeheartedly with new and original technologies as well as skilled artisans and state-of-the-art equipments.

| Address | 6241-6, Koibuchi, Kasama-shi, Ibaraki 309-1703, Japan | Telephone Facsimile |

+81-296-77-8171 +81-296-77-8186 |

|---|---|---|---|

| HP | http://www.canon-mold.co.jp/ | ||

| Division | Tomobe Sales Planning Div. | Contact person | Yutaka Sugai |

| Exhibit Items |

|

||

| Address | 1056-1 Dai Tsukubamirai-shi Ibaraki 300-2401 Japan | Telephone Facsimile |

+81-297-52-6195 +81-297-52-6197 |

|---|---|---|---|

| HP | http://www.kwmt.co.jp/ | ||

| Division | Mold Div. | Contact person | Yoshiyuki Wakasugi |

| Exhibit Items | |||

| Address | 292-1 Hina Fuji-city Shizuoka 417-0847 JAPAN | Telephone Facsimile |

+81-545-38-1142 +81-545-34-1795 |

|---|---|---|---|

| HP | http://www.mimolde.co.jp | ||

| Division | President | Contact person | Toshiyuki Miyagishima |

| Exhibit Items |

|

||

The significant technical traits of IKEX is to manufacture mold with electroforming.

Our high technique is able to manufacture low-price mold with various figure and size.

In the case of designated materal property, it is also possible to manufacture mold by Large-sized Machining center.

| Address | 1-3-1.MIYUKI-CHO KASUGAI-CITY AICHI-PREF JAPAN | Telephone Facsimile |

+81-568-33-4111 +81-568-33-9145 |

|---|---|---|---|

| HP | http://www.ikex.co.jp/ | ||

| Division | ELECTROFORMING&TOOLING DIVISION SALES SECTION | Contact person | HIDEKI HASHIDUME |

| Exhibit Items |

|

||

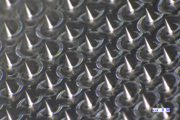

"Porous Nickel" is the world's first technology we developed. Nowadays, this tooling has come to be used all over the world. And we have been developing "MPM" tooling for the purpose of getting better quality and shorter cycle time in the process of injection molding and propose its new possibility.

| Address | 51 Jizo Yasura Konan Aichi 483-8111 Japan | Telephone Facsimile |

+81-587-54-5131 +81-587-54-8698 |

|---|---|---|---|

| HP | http://www.ktx.co.jp | ||

| Division | Sales Division | Contact person | Katsuya Sato |

| Exhibit Items |

|

||

Eagle factory is configured by members of young executive or having its qualifications from the companies belonging to Central division of Association Japan Die & Mold Industry to promote friendship among members, by various activity as training , workshops-tour and meetings.

Taking advantage of the cohesion of the organization involved in various projects related to mold for such as the press, plastic, die casting, casting, forging, rubber, glass, member companies commit to "manufacture originating from Japan".

| Address | IZUMI 2-21-28,HIGASHI,NAGOYA,AICHI, JAPAN461-0001 |

Telephone Facsimile |

+81-52-937-0269 +81-52-937-9889 |

|---|---|---|---|

| HP | http://www.japan-net.ne.jp/~eagle/index.html | ||

| Division | Contact person | ||

| Exhibit Items |

|

||