3DMaterials Co., Ltd,

| Exhibitor name |

3DMaterials Co., Ltd,

3DMaterials Co., Ltd,

|

|---|---|

| Booth NO. | 6A-401 |

| Website | www.3DMaterials.com |

| Phone number | +82-42-862-0595 |

| FAX | +82-42-862-597 |

| PR message | 3DMaterials offer the world largest LCD 3D printer that can printer 620mmx340mmx500mm parts. 3DMaterials developed PP like resin with an automaker which have similar impact strength of polypropylene. Parts 3D-printed by LuDiMen 620 with PPLike resin can directly substitute injection molded parts. |

| The Main Item |

|

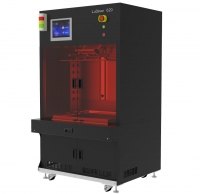

| The name of Item[1] | Large 3D Resin Printer LuDiMen 620 |

| Details[1] |

LuDiMen 620 is the world largest LCD 3D printer that can print 620mm x 340mm x 500mm parts. LuDiMen incorporated the emerging new 3D printing technology using LCD panel as image projection and UV LED as curing light source. LuDiMen series are optimized for customized mass production of automobile parts, assembly jigs and more. LuDiMen resin 3D printers offer highly accurate and detailed parts at industrial scale using patented 3DMaterials technology. LuDiMen 620’s 4K Ultra HD LCD screen offers the biggest build volume for high resolution mass customized manufacturing 3D prints. The standard layer thickness of LuDiMen 620 is 160μm, for the finest print, a layer thickness is recommended to be 75μm. The printing time for 500mm height part with 160μm standard setting and 3DMaterials‘s PPLike tough resin is as short as 18 hours. |

| The name of Item[2] | PPLike 3D Printing Tough Resin |

| Details[2] |

The UV curable resins which have viscosity low enough to be used in LCD 3D printers and toughness strong enough to replace automobile grade PP (polypropylene) parts directly. Unlikely competitors tough resins crack upon high speed impact, 3D parts printed with 3DMaterials PPLike resin survive against the automobile impact tests. The toughness of 3D printed parts is a mechanical property mainly decided by the tensile modulus and elongation at break. The high elongation indicate ductile property of the part and the high tensile modulus give the stiffness of the part. Conventional competitors’ tough or PP resins have high modulus (1GPas) but not enough elongation at break (30%~40%) which resulting in low impact strength; notched IZOD value, typically 30J/m or lower. PPLike® resin can be deformed up to 200% before the break with notched IZOD high value, 140J/m or higher |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Mold Components Formed Products J. PLASTIC FORMING MACHINES Injection Molding Machines L. CAD/CAM/CAE SYSTEM Rapid Prototyping System M. PROTOTYPE, MODELING, 3D PRINTING Prototype Manufacturer Service Bureau Resin Molding Machine RP Machine N. PARTS PROCESSING TECHNOLOGY Plastic Processing |