Exhibitor Search

Exhibitor Detail

| Exhibitor name |

丸紅情報システムズ株式会社

MARUBENI INFORMATION SYSTEMS CO.,LTD.

|

|---|---|

| Booth NO. | 6A-402 |

| Address |

〒150-0002 東京都 渋谷区渋谷三丁目12番18号 渋谷南東急ビル Shibuya Minami Tokyu Building, 3-12-18, Shibuya, Shibuya-ku, Tokyo,Japan |

| Website | http://www.marubeni-sys.com/ |

| info@marubeni-sys.com | |

| Phone number | +81-3-5778-8888 |

| FAX | +81-3-5778-8999 |

| PR message | With lots of global experiences, ATOS 3D scanner and tebis high-end CAD/CAM are now common for process optimization at die and mold development. Also you can find unique ideas of how the “kaizen” should be accelerated with the world No.1 share 3D printer: Stratasys. |

| The Main Item |

ATOS 3D scanner(GOM), 3D Printer(Stratasys), High-end CAD/CAM(tebis)

|

| The name of Item[1] | 3D Printer |

| Details[1] |

|

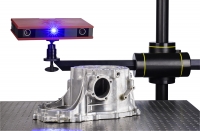

| The name of Item[2] | ATOS 3D scanner (GOM mbH) |

| Details[2] | The ATOS series of industrial optical 3D scanners provide accurate scans with detailed resolution at high speeds. ATOS delivers three-dimensional measurement data and analysis for industrial components such as sheet metal parts, tools and dies, turbine blades, prototypes, injection molded parts, castings, and more. Instead of measuring single points or with a laser, ATOS captures an object's full surface geometry and primitives precisely in a dense point cloud or polygon mesh. ATOS is widely utilized in various industries, and can measure different object sizes, surface finishes, and shape complexities: •Highly accurate 3D measurements •Detailed, high-resolution scans •Quick data collection •Advanced inspection functionality •Complete dimensional analysis •Comprehensive reporting

|

| The name of Item[3] | ARAMIS Optical 3D Deformation Analysis (GOM mbH) |

| Details[3] | ARAMIS helps to better understand material and component behavior and is ideally suited to monitor experiments with high temporal and local resolution. ARAMIS is a non-contact and material independent measuring system providing, for static or dynamically loaded test objects, accurate: •3D surface coordinates •3D displacements and velocities •Surface strain values (major and minor strain, thickness reduction) •Strain rates ARAMIS is the ideal solution for... •Determination of material properties (R- and N-values, FLC, Young's Modulus, etc...) •Component analysis (crash tests, vibration analysis, durability studies, etc...) •Verification of Finite Element Analysis

|

| The name of Item[4] | High-end CAD/CAM System Tebis |

| Details[4] | Tebis is an integrated CAD / CAM system that can support the whole manufacturing process. We’ll present Tebis V4.0R2 (the newest version) focusing on a module specialized in the MIKOMI surface making. Also we’ll show the availability of how the special tool (HPC) works in the current Tebis functions. Please find its performance with a sample model which we made with Mitsubishi Hitachi Tool Co., Ltd. *features* *Speeding up of the MIKOMI surface making Relief surface making of positibe R and negative R The surface of hard touch and weak touch making *The correspondence of special tool (HPC) Reproduction of the faithful stock model after processing Reduce processing time Improvement of the tool life and cutting condition

|

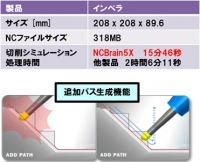

| The name of Item[5] | Processing Simulation & Milling Optimization System NCBrain 5X |

| Details[5] | With NCBrain 5X, we’ll provide a lots of milling optimizing functions. Moreover, the system includes collision simulation targeting all axes processing from 3 axis to 5axis. NCBrain 5X brings you the high level processing simulation & milling optimization. *features* *Ultra-fast Cutting Simulation The overwhelming calculation speed. *Ultra-high Quality Optimization Simulation Improvement of safety thanks to the function of an additional toolpath Improvement of processing efficiency thanks to the function of the deletion of the air cut *Ultra-high Level Standardization DB for Milling Condition The standardized database special to each companies

|

| Category of Exhibit Items |

K. PRECISION MEASURING, OPTICAL MEASURING MACHINES & INSTRUMENTS 3D Coordinate Measuring Machines & Instruments L. CAD/CAM/CAE SYSTEM CAD/CAM/CAE System M. PROTOTYPE, MODELING, 3D PRINTING Resin Molding Machine |