Exhibitor Search

Exhibitor Detail

| Exhibitor name |

Shenzhen Aidely Precision Technology Co., LTD

Shenzhen Aidely Precision Technology Co., LTD

|

|---|---|

| Booth NO. | 6A-912 |

| Website | www.aidely.net |

| sales02@aidely.com | |

| Phone number | 86 755 28137033 |

| FAX | 86 755 28137066 |

| PR message | Founded in 2000, Shenzhen AIDELY Electromechanical Co., Ltd. is a manufacturer of precision machinery components and fixtures for industries such as medical equipment, Food machinery, Aerospace, solar energy, electronics, optical communication,office automation, Industrial equipment, domestic appliance etc. Today, we have set up a new factory in Longhua area, Shenzhen city, most of workers are highly-skilled technicians. With high-precision tools and instruments, including CNC machining centers, CNC lathes, EDM machines, high-precision ID/OD grinders, surface grinders, Swiss-made high-precision height gage, and Coordinate MeasuringMachine(CMM). We are professional at high precision machinery such as CNC milling,turning, machining center etc, various products with small amount are welcome. |

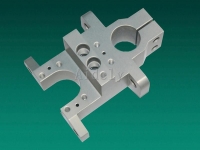

| The Main Item | The Extraman base,material A16061, harden Anodizing |

| The name of Item[1] | parts for liquid food packing machine, material A17075, golden Anodizing |

| Details[1] | Toki tube parts of high-end liquid food packaging equipment Material: 7075-T6 The size: 135 * 105 * 56 Surface treatment: hard anode oxidation film thickness 20 ± 3 um Processing time: 3 hours Processing equipment: four shaft linkage processing center, etc

|

| The name of Item[2] | Elcentric shaft for food packing machine, hardness:60~62HRC |

| Details[2] | precision machined Carbon Steel Parts / Off-center shaft >>>20CrNiMo material, turned and ground. >>>Finish hardness HRC 60-64, Ra 0.4. >>>tolerance 0.01 mm, >>>The 2 axises required absolutely parallelism >>>Material: 20CrNiMo >>>Machining hours: 7 hours >>>Equipment: 4 axis CNC mill, CNC lathe, OD grinder, etc >>>Feature: Transition from big OD to small OD and off-set. Axis offset 10+0.05/-0.00,// 0.05. Total runout 0.01, OD tolerance h5, Roughness to Ra 0.4. Case hardening heat treatment deformation

|

| The name of Item[3] | Engineering plastic parts |

| Details[3] | ***Key point: Cnc Precision Machining plastic part ****Material: POM, plastic **** Easy to deformed, flatness and perpendicularity is 0.05mm.. ****Engineer consultation to your design for production improvement and cost saving. ****ISO9001: 2008 certified. **** Customized CNC machining precision part.

|

| The name of Item[4] | Welding Flange, material: SUS 304 |

| Details[4] | Sub-assembly in Solar panel production equipment 2 big rings (easily deformed) CNC turned and then welded together. Inside are air and water passages. Finish with high-vacuum leak helium test.

|

| The name of Item[5] | Lithium cutter,accuracy of thread:0.01 |

| Details[5] | Precision Threaded assembly ===After threaded together, the assembly has to meet perpendicularity 0.02 mm, co-axiality 0.05 mm. 40Cr material, blackening finish ===Available in various surface treatment and various materials. ===To support in New Product Introduction, our experienced program managers are ready to accommodate any of your requirements. ===ISO9001: 2008 certified.

|

| The name of Item[6] | Food packing machinery, SUS304 |

| Details[6] | precision Stainless Steel Parts ===Key point: Odd-shape part ( Complex CNC process) ===Material: 420 CNC milling ===Accuracy: ±0.012mm ===Craft route: CNC lathe-Miller-Grinding-Wire cutting-Miller*2-CNC miller-Nipper-Riveting-Grinding-Electro polishing

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Mold Components Formed Products C. MACHINE ACCESSORY Accessories & Attachments N. PARTS PROCESSING TECHNOLOGY Cutting Processing Grinding Processing Plastic Processing Precision Processing Tooling, Steel Materials |