Exhibitor Search

Exhibitor Detail

| Exhibitor name |

ダイジェット工業株式会社

DIJET INDUSTRIAL CO., LTD.

|

|---|---|

| Booth NO. | 6B-802 |

| Address |

〒547-0002 大阪府 大阪市平野区加美東2-1-18 2-1-18, Kami-Higashi, Hirano-ku, Osaka 547-0002, Japan |

| Website | http://www.dijet.co.jp |

| info_hp@dijet.co.jp | |

| Phone number | +81-6-6791-6781 |

| FAX | +81-6-6793-1221 |

| PR message | DIJET will exhibit new cutting tools, adopted new PVD coated grade DH102 & DH103 for high hardened material. One-Cut Ball 70 realizes high efficient machining and longer tool life. MIRROR series & QM series which improved cutting performance. In addition, we introduce Solid modular head for aluminum alloy and Spot facing drill TLDM type etc. |

| The Main Item |

4 flutes Solid Carbide Ball Nose End Mill for high hardened material up to 70HRC.

|

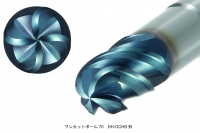

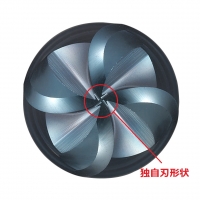

| The name of Item[1] | One-Cut Ball 70 |

| Details[1] | 1.Multi-flutes solid carbide ball nose end mill for high hardened material up to 70HRC. From roughing to finishing. 2.High efficient machining is possible due to 4 flutes. 3.High rigidity of tool and un-equal pitch control the vibration. 4.Adopting unique flute geometry at the center point achieved good chip ejection & stable machining. 5.Achieved low cutting force due to high helix angle, and provided good cutting performance. 6.Adopted new PVD coated grade DH102 by combination of newly developed DH COATING & super micro-grain carbide suitable for high hardened material. Achieved longer tool life. 7.Size range:3 -12mm dia. Tolerance of R:±8μm.

|

| The name of Item[2] | New radius insert GRM type for MIRROR-BALL BNM/MBN type |

| Details[2] | 1.Radius insert for profile milling. 2.Reduced the hand finishing and try out times by improved surface quality. 3.Body durability is higher ball nose end mill with same radius, therefore prevents chattering problem, and larger pick feed improved machining efficiency. 4.Possible to high precision & high efficient machining even in case of normal speed machine. 5.Adopted new PVD coated grade DH102 suitable for high hardened material, and PVD coated grade JC8015 for general steel. 6.Stock size:Dc16-R5,Dc20-R6,Dc25-R8,Dc30-R10 7.Corner radius accuracy of inserts:below ±12μm

|

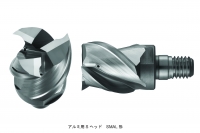

| The name of Item[3] | Solid modular head S-HEAD for aluminum alloy SMAL type |

| Details[3] | 1.Solid modular head SMAL type showed the same performance as the solid end mill, by the combination with carbide shank MSN type. And, overhung length is of wide range, due to many variation in carbide shank MSN type. 2.Adopted the cutting edge geometry suitable for aluminum alloy machining. Positive geometry with helix angle 45deg. & rake angle 20deg. achieved sharpness and high precision machining. 3.Achieved both good chip ejection and high efficient machining due to 3 flutes. 4.Adopting coolant hole can be possible surely coolant supply to cutting edge, so prevented welding and improved chip ejection. 5.Adding over size type(Dc>Ds) also enables machining at corner wall. 6.Size range:18 - 32mm dia. Flute length:1D(Dc=l).

|

| The name of Item[4] | spot facing drill TLDM type |

| Details[4] | 1.Spot facing drill with point angle of 180deg.(flat face) have extensive line-up(3 to 12mm dia. at every 0.1mm dia.). 2.Stable drilling without pilot hole even if drilling slope surface and crossed hole. 3.Due to wide flute design, TLDM type achieved excellent chip control. 4.Controlled burr in case of drilling thin plate. 5.Reduced cutting force by 20% compared with competitor.

|

| The name of Item[5] | SKS EXTREME EXSKS type for high feed machining |

| Details[5] | 1.Next-generation high feed machining cutter advanced conventional tool. 2.Possible to high feed machining on fz=2mm/t in case of Max. depth of cut (ap)= 3mm. 3.Economical double-side insert (6 corners). 4.Insert thickness: 7.5mm improved strength by 1.5 times compared with conventional tool. 5.Only single screw clamp prevents movement of inserts with changing corner of inserts easily. 6.Wide application: 2 insert grades JC7560 & JC8118 are suitable for general steel, cast iron, high hardened steel & stainless steel. New PVD coated grade JC8118 is the first recommendation for mold steel & high hardened steel less than 50HRC and achieved longer tool life. 7.Size range: 80 - 160mm dia.

|

| The name of Item[6] | WILD RADIUS WDR type |

| Details[6] | 1.Indexable radius cutter with highly efficient cutting for roughing process. 2.Body durability is higher than conventional ball nose end-mill, therefore prevents chattering problem. 3.Adopting uneven stock material. (Max. depth of cut: 18mm). 4.Due to key on bottom of inserts, single screw clamp prevents movement of insert with changing corner easily. 5.Wide application: 2 insert grades JC7560 & JC8118 are suitable for general steel, cast iron, high hardened steel & stainless steel. New PVD coated grade JC8118 is the first recommendation for mold steel & high hardened steel less than 50HRC and achieved longer tool life. 6.Size range: 40 - 125mm dia.

|

| The name of Item[7] | New PVD coated grade DH103 for MIRROR-BALL BNM/MBN type & MIRROR-RADIUS RNM/MRN type |

| Details[7] | BNM type & RNM type inserts are adopted new PVD coated grade DH103 for high speed machining in high hardened material.

|

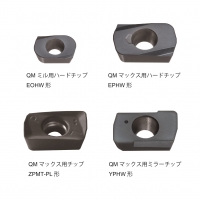

| The name of Item[8] | New insert for new generation high feed mill QM MILL & QM MAX |

| Details[8] | 1.QM MILL MPM/PME type Added corner radius R2 insert adopted new PVD coated grade DH102 suitable for high hardened material(HARD INSERT EOHW type). 2.QM MAX MQX/QXP type 1)Added new inserts suitable for roughing & finishing in high hardened material(MIRROR INSERT YPHW type for finishing side & bottom face, contouring, HARD INSERT EPHW type for roughing). Both inserts are adopted new PVD coated grade DH102 for high speed machining in high hardened material. 2)Added corner radius R0.3 insert(MIRROR INSERT YPHW type). 3)Series expansion, shoulder milling insert ZPMT-PL type from semi-finishing to finishing side & bottom face. Adopted 3 grades: PVD coated grade DH102, JC8015 and cermet CX75.

|

| The name of Item[9] | Series expansion, Super finishing mill FINISH JET MILL FJM type |

| Details[9] | All type, easy to adjust the face run out by adjusting the cartridges. 1.FJM type Adopted the combination of 2 finishing & 2 roughing cartridges gives stable finishing quality in case of Max. ap=0.3mm. Consolidate to one process of semi-finishing & super finishing. 2.FJM-F4 type(For high efficiency of super finishing) In case of ap=below 0.1mm, 4 finishing insert type achieved further efficient machining. 3.FJM-BD type Extensive line-up, for shoulder milling. Install insert for BACK DRAFT DBD type. 4.Size range(every type):80 - 250mm dia.

|

| The name of Item[10] | New composite material CERMETAL CT500 series |

| Details[10] | --Merits of CT500 series-- 1.Good balance of hardness and toughness 2.Good slipping and anti-galling properties 3.Good resistance to oxidation at high temperature 4.High strength at high temperature 5.Light weigh 6.Low thermal conductivity 7.Better machining performance than ceramics 8.Minor metal(W and Co) are not included

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds D. CUTTING TOOLS Cemented Carbide Tools Cemented Carbide Tips Diamond Tools Others |