株式会社ナノソフト

| Exhibitor name |

株式会社ナノソフト

Nanosoft CO.,LTD.

|

|---|---|

| Booth NO. | 2-255 |

| Address |

〒222-0033 神奈川県 横浜市港北区新横浜1-3-1 新横浜アーバンスクエア 1-3-1,Shinyokohama,Kohoku,Yokohama,kanagawa,222-0033 |

| Website | http://nano-soft.co.jp |

| Phone number | +81-45-473-3015 |

| PR message | Nanosoft proposed to Die & Mold Engineer by 3D Power!! 3DQuickPress is a world popular 3D Progressive Die Designing Software 3DQuick- Form and 3DSimSTAMP is Metal forming Simulation Software IMOLD is the Plastic Mold Designing Software. |

| The Main Item |

|

| Movie |

|

| The name of Item[1] | 3DQuickPress |

| Details[1] |

Powerful Unfold, a feature recognition technology, can handle native SOLIDWORKS? sheet metal parts for imported data, and provide a knowledge base for spring back and bend allowance. Form features can save valuable time from die designs and give them more design productivity tasks. Strip Layout Manager provides users with intuitive tools to quickly complete the strip simply by drag & drop command with instant graphical feedback. Die Set Design begins after finishing the strip layout. 3DQuickPress? will automatically create all punches defined in the strip design. PRL assists users to insert home-made components into die sets structure with minimal manual operations. |

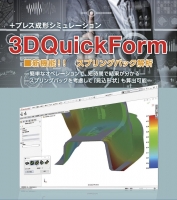

| The name of Item[2] | 3DQuickForm |

| Details[2] |

Tool designers may fully concentrate on the die design processes and virtual try-outs. Simulations are run in project driven manner and support multiple projects; thus streamlining design feasibility study, process simulation, and optimization. Simulation results are displayed to show initial blank shape, different material thickness, and stress/strain distribution. Customizable material database allows designers to test their design with different materials. Fully integrated with SOLIDWORKS, 3DQuickForm is easy to use and rich in functions. |

| The name of Item[3] | 3DSimSTAMP |

| Details[3] |

|

| The name of Item[4] | IMOLD for SOLIDWORKS |

| Details[4] |

|

| The name of Item[5] | 3DSimCOST |

| Details[5] |

|

| The name of Item[6] | Cast-Designer |

| Details[6] |

Cast-Designer combined the KBE system, design system and last CAE technology together; it is a tailor-designer casting planning & simulation system for all casting process. Cast-Designer could be used for high pressure die casting, low pressure die casting, gravity casting for sand, gravity casting for permanent mould, investment casting and many others. |

| Details[7] |

|

| Category of Exhibit Items |

L. CAD/CAM/CAE SYSTEM CAD/CAM/CAE System |