EXHIBITOR SEARCH

三井精機工業株式会社

| Exhibitor name |

三井精機工業株式会社

MITSUI SEIKI KOGYO CO.,LTD.

|

|---|---|

| Booth NO. | B-732 |

| Address |

〒350-0193 埼玉県 比企郡川島町八幡6-13 6-13 Hachiman,Kawajima-machi,Hiki-gun,Saitama 350-0193 |

| Website | http://www.mitsuiseiki.co.jp |

| PR message | PJ812 is renowned as the "Ultimate Mother Machine" that realizes exceptional high quality in profile machining with Jig Borer level positioning accuracy. J350G's advanced features include the out-feed stroke 53mm extended from previous 2mm, significantly improving the productivities in contour chopping grinding process for various diameter holes. |

| The Main Item |

|

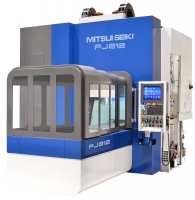

| The name of Item[1] | Precision Profile Center PJ812 |

| Details[1] |

(2)Table Working surface:1,200mm×800mm (3)Spindle taper/rotation speed:BT40/30,000min-1 ・Ultimate mother machine realizes Jig borer high accuracy positioning and High accuracy contour machining. ・Planer type symmetric construction reduces heat deformation. ・Achieves 0.1um axis feed,using a new"Mitsui Seiki"designed slide way mechanism,and adapting centralized cooling system for ballscrews,slideways and critical surfaces. ・New multi sensor thermal growth monitoring system controls Z axis thermal displacement approximately 35% better than previously used technologies. ・New PJ812 design minimizes the distance between the spindle center and Z axis drive thereby improving the static rigidity of the system 6 times more than conventional machine designs. ・New Energy saving circuitry reduces"idle time"power consumption by 90% and compressed air consumption by 40% over previous designs. |

| The name of Item[2] | High Precision Jig Grinder J350G |

| Details[2] |

(2)Table Working surface:700mm×350mm (3)Spindle wheel infeed travel:-3mm~+50mm ・Grinding wheel in-feed range of -3~+50mm enables continuous grinding of multiple features and a variety of hole sizes to be processed with one grinding wheel. ・15"touch panel LCD screen and specially developed conversational style programming software (G-MAPS) is provided as a standard feature. ・Whole machine enclosure covers for improved safety and ergonomics are provided standard. ・New compact design layout incorporates several ancillary devices including coolant systems (Machine overall foot print reduced 50% from previous model). |

| Category of Exhibit Items |

B. METAL MACHINE TOOLS Grinding Machine Machining Centers |