EXHIBITOR SEARCH

株式会社テクノクラーツ

| Exhibitor name |

株式会社テクノクラーツ

Technocrats Corporation

|

|---|---|

| Booth NO. | B-121-28 |

| Address |

〒732-0824 広島県 広島市南区的場町1-5-5 1-5-5 Matobacho, Minami-ku, Hiroshima, Japan |

| Website | http://www.technocrats.co.jp |

| Phone number | +81-82-264-1010 |

| PR message | 'Suppon' enables impossible undercut configurations. ・Make mold simple and smaller. ・Reduce mold design restriction. ・Reduce mold die machining. ・Make undercut molding more reliable . |

| The Main Item |

|

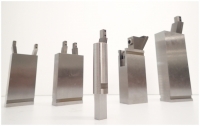

| The name of Item[1] | Next Generation Undercut Molding Unit |

| Details[1] |

'Suppon' can; / set you free ofrestricted mold design that the conventional undercut molding mechanism has involved so far. / reduce your mold die machining much more than ever thanks to 'Suppon' making your die simple and smaller. / cut back the injection cost resulting from employing a smaller injection machine in which your smaller 'Suppon' mold die is set. / make your undercut molding mechanism simple by the gimmick 'Suppon' has. / make your undercut molding mechanism more reliable thanks to the high precision of 'Suppon', that is a complete factory-assembled unit in which all the parts you've machined, assembled and adjusted at site so far are packed in one unit. |

| Details[2] |

【Let's change into Stamping parts from Cutting parts!】 Our Precision Motor case Transfer press tool Die do not lose in a Cutting part. We can transfer die design and production in the motor cover and motor cover. The motor case is important for accurate roundness and concentricity and bearing bore shape. I have the skill and experience to provide a stable supply of the product. 【We can integrated one stamping parts of two stamping parts!】 We can be Low Cost efficiency , Lighter, Smaller, High strength SHEET FORGING:Three-dimensional stamping product is available . (Increased thickness of the plate) Combined processing:In the PRESS DIE,PRESS TOOL to produce multiple stamping products, and combines. |

| The name of Item[3] | Chips-less Pipe cutters , Automatic pipe processing line |

| Details[3] |

■Full Automatic Line The ease in operation has increased the productivity of each machine. And as a result, the processing lines of manufacturers using an Osuga machine can be fully automated. ■CNC Pipe benders Liquid Crystal Color touch panel is introduced for equipment operation. Operation method is same as exisiting but more simple. Operation by using Touch panel screen is simple and required input information are minimized for easy operation. ■Pipe cutters The Osuga automatic pipe and tube cutting machine series - friendly to the environment and people. ■Pipe end shapers Now, Osuga machine has made ease of operation and increased productivity a reality. Until now, the plasticity processing method could not produce a machine capable of complicated and accurate pipe end formation. As with all our products, automatic feeder and product inspection devices are available. |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Components Formed Products |