ABOUT THE SHOW

Exhibitor Search

Exhibitor Detail

| Exhibitor name |

ソマックス株式会社

SOMAX CO.,LTD.

|

|---|---|

| Booth NO. | 2-813 |

| Address |

〒537-0023 大阪府 大阪市東成区玉津1丁目7番17号 1-7-17,Tamatsu,Higashinari-ku,Osaka,537-0023 |

| Website | http://www.somax.co.jp |

| info@somax.co.jp | |

| Phone number | +81-6-6976-1108 |

| FAX | +81-6-6977-5702 |

| PR message | CLIPIKA ACE is a mold cleaning machine which removes stubborn dirt from molds without any damage. WATER REAMER is a machine which removes scale and rust of the mold cooling pipe. MOLHEI is a mold welding machine which welds easily without generating ultraviolet light. |

| The Main Item |

MOLD CLEANING MACHINE[CLIPIKA ACE],MOLD COOLING PIPE CLEANING MACHINE[WATER REAMER]

|

| The name of Item[1] | MOLD CLEANING MACHINE [CLIPIKA ACE] |

| Details[1] | CLIPIKA ACE is a mold cleaning machine which is remove stubborn dirt from the molds without any damages. The life span and shot number of molds can be extended by using CLIPIKA ACE and its original cleaning solution. Type III is a new type of CLIPIKA ACE series which can run the machine with Eco mode (saves 40 % of electricity). Touch panel is installed to operate the machine. Support 3 languages (Japanese, Chinese, and English). CLIPIKA ACE OPT is a mold cleaning machine for optical parts molding which is able to remove dirt without damaging Nickel layer by synergy of using its original cleaning solution.

|

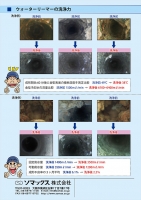

| The name of Item[2] | MOLD COOLING PIPE CLEANING MACHINE [WATER REAMER] |

| Details[2] | WATER REAMER is a mold cooling pipe cleaning machine which removes solid rust stuck to the inner wall of a mold cooling pipe by dissolving the rust and scale, and put back into its original condition. If you circulate hydrochloric acid, scale and rust will not dissolve and sludge occurs. The sludge might block the cooling pipe. But WR-5 dissolves rust and scale well, so you can avoid the cooling pipe get blocked.

|

| The name of Item[3] | MOLD WELDING MACHINE [MOLHEI] |

| Details[3] | MOLHEI is a mold welding machine that is able to weld easily without generating ultraviolet light. Since welding is accomplished by touching the electrode to the target area, there is no missing the target. No pinholes, sink marks, warping or twisting due to heat, for safe and secure welding even of the corners and edges of the mold. Employs a continuous electric welding system in the repair of precision molds for detailed welding at a 1/10 millimeter level. Reduces both the effort required to remake the mold and the time spent running to the welder.

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds F. SURFACE FINISHING, MODIFYING, WELDING Die & Mold Mending System Welding Machines Washing Machine Others G. ALL SORTS OF OIL, CHEMICAL PRODUCTS Antirust Cleaner Others |