- HOME>

- Exhibitor Search

Exhibitor Search

Exhibitor Detail

| Exhibitor name |

カールツァイス株式会社

Carl Zeiss Co., Ltd.

|

|---|---|

| Booth NO. | 911 |

| Address |

〒564-0062 大阪府 吹田市垂水町3-35-22 3-35-22, Tarumi-cho, Suita-shi, Osaka, 564-0062 |

| Website | http://www.zeiss.co.jp/imt |

| info.metrology.jp@zeiss.com | |

| Phone number | +81-6-6337-8031 |

| FAX | +81-6-6337-7804 |

| PR message | We show Multisensor CMM ZEISS O-INSPECT, intelligent digital measuring projector ZEISS O-SELECT, compact and high-performance 3D sensor ZEISS COMET L3D2. More, we will also introduce softwares, such as a valid measurement data management system ZEISS PiWeb for the realization of the Industry 4.0. |

| The Main Item |

Multisensor CMM O-INSPECT, digital measuring projector O-SELECT, 3D sensor COMET L3D2, PiWeb

|

| The name of Item[1] | Digital measuring projector ZEISS O-SELECT |

| Details[1] | Thanks to fully automatic setting of both illumination and focus, measuring errors due to operator influence are eliminated. At the mere push of a button, ZEISS O-SELECT evaluates the characteristics and documents the results – also in a professional report if needed. In production environments, optical and contact coordinate measuring machines are increasingly replacing manual equipment such as goniometers, gauges and profile projectors. However, the influence of the operator with these manual tools must not be disregarded. With O-SELECT, ZEISS is reducing this influence to a minimum. Thanks to its high level of automation and ease of use, complex measurements can be completed quickly, traceably and reproducibly.

|

| The name of Item[2] | Multisensor Measuring Machines O-INSPECT |

| Details[2] | O-INSPECT multisensor measuring machines from ZEISS enable you to optimally measure each characteristic – optically or by contact. An important feature: O-INSPECT delivers reliable 3D accuracy compliant with ISO standards at a temperature range of 18-30°C. An added highlight: CALYPSO software not only delivers results easily, but also simplifies the detection and identification of the causes of errors.

|

| The name of Item[3] | 3D sensor ZEISS COMET L3D2 |

| Details[3] | COMET L3D2 uses innovative, maintenance-free and cost-effective LED lighting technology with a long life. With its new and unique LED pulse mode delivering a high light output, the system guarantees excellent measurement results even in difficult ambient conditions. The sensor housing with the proven single-camera technology from ZEISS Optotechnik and the complete measurement setup are ultracompact and lightweight for easy portability. 3D data acquisition with the COMET L3D2 is sensationally fast. The extremely short measurement time and the simple-to-use software allow efficient measurements. Delivering excellent data quality and highly accurate results, COMET L3D2 is also ideal for demanding applications in quality assurance. Areas of application: • Quality control / inspection • Mold and model making • Design • Rapid Manufacturing • Reverse Engineering • Archaeology, documentation of art-historical objects, etc.

|

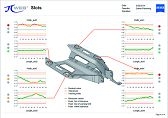

| The name of Item[4] | ZEISS PiWeb - Quality Data Management |

| Details[4] | ZEISS PiWeb is a scalable IT solution for quality data management. You can organize the information flow resulting from Industry 4.0 and therefore enhance the quality of your products and productivity. Highlights: • Scalable quality data management • Manufacturer-independent and flexible: supports many data types such as DMO, DFQ, CSV, TXT, PCN and many more • Easy generation of even complex report templates • Simple and fast knowledge sharing through intuitive reports in real time • Interactive access to CAD displays, detailed information and additional data with a single mouse click • Extensive statistical evaluations • Secure internet access via https connection • Modern, high-performance database technology

|

| Category of Exhibit Items |

K. PRECISION MEASURING, OPTICAL MEASURING MACHINES & INSTRUMENTS Measuring Machines and Instruments 3D Coordinate Measuring Machines & Instruments Others |