- HOME>

- Exhibitor Search

Exhibitor Search

Exhibitor Detail

| Exhibitor name |

大垣精工株式会社

OGAKI SEIKO CO., LTD

|

|---|---|

| Booth NO. | 601-45 |

| Address |

〒503-0945 岐阜県 大垣市浅西3-92-1 3-92-1 ASANISHI OGAKI-CITY GIFU-PREFECTURE JAPAN |

| Website | http://www.ogakiseiko.co.jp |

| osk@ogakiseiko.co.jp | |

| Phone number | +81-584-89-5811 |

| FAX | +81-584-89-5545 |

| PR message | High productivity and stable quality by high precision progressive die. With high stroke stamping and remarkable durability, achieve cost reduction. Be able to fablicate many kinds of die including transfer, fine blanking, layered yoke, ceramic tip, and catalyser. |

| The Main Item |

Layered yoke / Base plate & case for vibration motor

|

| The name of Item[1] | Layered Yoke |

| Details[1] | Material: Iron, Nickel magnetic alloy Thickness: 0.2mm Comments: Fine dowel caulking in tight width Process conversion (Sintering to Stamping) 50% cost reduction by process conversion

|

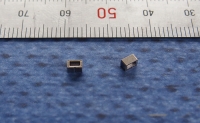

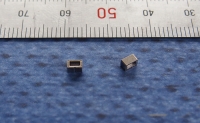

| The name of Item[2] | Case for Vibration Motor of Cell Phone |

| Details[2] | Compress the material from 0.3mm to 0.15mm and then make hight 4 times of inner diameter by burring process

|

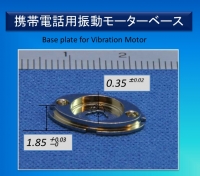

| The name of Item[3] | Base Plate for Vibration Motor of Cell Phone |

| Details[3] | Material: SPCC Thickness: 1.85mm Comments: No Die roll to secure magnetic force Thickness variation is less than 0.03mm

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Formed Products |