Top > Exhibitors&Exhibit Items > Exhibitor/Exhibits Search

Exhibitor Detail

| Exhibitor name in Japanese |

株式会社CAEソリューションズ |

|---|---|

| Exhibitor name in English |

CAE Solutions Corp. |

| Booth NO. | 351 |

| Address in Japan |

〒102-0072 東京都 千代田区飯田橋2-1-10 TUGビル8F |

| Website | http://www.cae-sc.com/ |

| sales@cae-sc.com | |

| Phone number in Japanese |

03-3514-1506 |

| FAX in Japanese | 03-3514-1507 |

| PR message | Recently, it is popular to use simulation software for plastic injection molding, metal press, and deformation processing. We will have a consulting corner for beginners or users. e.g. How to use these simulation software efficiently? Which software is useful for your company? etc. Please feel free to come to our booth. |

| The Main Item |

Consulting, Moldflow, Simpoe-Mold, SOLIDWORKS Plastics, Abaqus

|

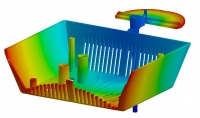

| The name of Item[1] | Autodesk Simulation Moldflow |

| Details[1] | There is a wide range user of the world use plastic injection molding simulation software "Autodesk Simulation Moldflow" as a tool to optimize inspection and the die design at the time of the plastic parts design, a molding process by an abundant materials database and longtime technical accumulation. We provide the output which a support tool of introduction, the acquisition, the plain menu constitution, spot are easy to understand so that an engineer concerned with a designer, die production, molding can perform the interpretation of setting of the simulation and the result easily. Can see it under the influence that wall thickness, a gate position, materials, a shape, fiber orientation give to a completion product. It supports a wide parts shape such as thin wall, thick wall, and solid cast . it contribute to quality improvement, designup, lightweighting, materials reduction in the period when it is various one which you can inspect and has a shorter it before completing a design .

|

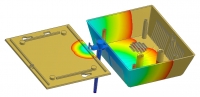

| The name of Item[2] | SIMULIA Simpoe-Mold |

| Details[2] | In SIMULIA Simpoe-Mold, a user predicts a production defect at the initial stage of plastic parts and the mold design and is simulation software to evade it. I reduce the rework of the expensive mold and improve the quality of parts and shorten time to market injection and shorten time for a product cycle. The Simpoe-Mold plastic ejection simulation software is a support tool for all one engaged in a product designer, a mold designer, a mold maker, the plastic industry including the plastic parts maker. I comprise a shell and solid mesh and cope with the molding of the parts of the complicated shape. In addition, the simulation of the higher process including gas support ejection, a coejection mold, 重屈折, an overmold, a multi-shot or the multi-domain ejection can be realized.

|

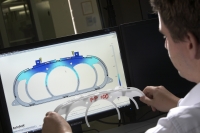

| The name of Item[3] | SOLIDWORKS Plastics |

| Details[3] | See it by the flow in the injection molding process of the plastic parts which designed in SOLIDWORKS; become it, and can examine problems at the time of the molding beforehand. It evaluate production efficiency at the time of a design quickly and lose the recomposition of the expensive die and improve the quality of parts and enable shortening for time to market injection.

|

| Category of Exhibit Items |

L. CAD/CAM/CAE SYSTEM CAD/CAM/CAE System |