Top > Exhibitors&Exhibit Items > Exhibitor/Exhibits Search

Exhibitor Detail

| Exhibitor name in Japanese |

株式会社 関プレス |

|---|---|

| Exhibitor name in English |

Seki Press Co.,Ltd. |

| Booth NO. | 501-14 |

| Address in Japan |

〒316-0013 茨城県 日立市千石町4-3-20 |

| Address in English |

4-3-20, Chikoku-cho, Hitachi-shi, Ibaraki |

| Website | www.sekipress.jp |

| spc-sugita@jsdi.or.jp | |

| Phone number in Japanese |

0294-36-0300 |

| FAX in Japanese | 0294-34-5947 |

| Phone number in English |

+81-294-36-0300 |

| FAX in English | +81-294-34-5947 |

| PR message | The world first technology WARISAKI and its application products are going to be presented. Warisaki is a technology to split metal by stamping. Using WARISAKI, complex 3D shape could be made by stamping, with no need of welding or die casting. Therefore, cost reduction and Quality improvement are promising. This technology could be used in various kinds of industry. |

| The Main Item |

The world first technology WARISAKI

|

| The name of Item[1] | Patent Technology WARISAKI |

| Details[1] | Warisaki is a patented technology to split metal by stamping. By using Warisaki, integral molding of complex 3-D shape is realized by stamping. It enables to make 3-d complex shape parts in a progressive die, which have been made by cutting or die-casting till now. Through Warisaki, large cost reduction, weight saving and quality improvement could be realized.

|

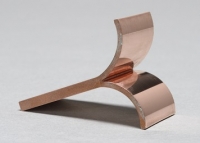

| The name of Item[2] | Warisaki Application-- T shape fitting |

| Details[2] | After splitting a piece of metal, we form it into T shape. With no need of welding, cost would be reduced largely and the strength would be improved.

|

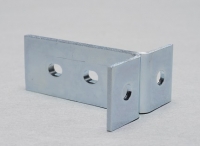

| The name of Item[3] | Warisaki Application-- Cup shape connector |

| Details[3] | After splitting one piece of metal, we form it into a cup shape connector. Mading in a progressive die, the speed is much faster, which realizes cost reduction.

|

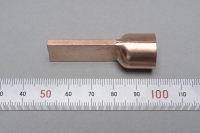

| The name of Item[4] | Warisaki Application-- Busbar Terminal |

| Details[4] | Warisaki enables to make this complex shape busbar in a progressive die, which has been made by cutting or die-casting till now. Compared with die-casting, working process is decreased largely. Furthermore, no heat treatment makes it energy-saving. Thus, cost could be cut down by 75%.

|

| The name of Item[5] | Warisaki Application-- (dis)similar metal joining |

| Details[5] | To join copper and aluminum, we split a copper plate and sandwich a aluminum plate to make a three-layer form. Compared with the traditional method, joining would be much more stable.

|

| The name of Item[6] | Internal Splitting |

| Details[6] | These brass bar and stainless bar are splitted by stamping. Being splitted, the metal strength improves largely.

|

| The name of Item[7] | splitting the outer circumference of pipe or aperture surface |

| Details[7] | This pipe and its aperure surface is splited from the outer circumference.

|

| The name of Item[8] | Splitting extrusion molding parts |

| Details[8] | This molding part is splited by stamping.

|

| The name of Item[9] | 3 parts splitting |

| Details[9] | We split one piece of metal into 3 parts by stamping.

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Formed Products N. PARTS PROCESSING TECHNOLOGY Plasticity Processing |