Top > Exhibitors&Exhibit Items > Exhibitor/Exhibits Search

Exhibitor Detail

| Exhibitor name in Japanese |

株式会社ワークス |

|---|---|

| Exhibitor name in English |

WORKS Co.,Ltd |

| Booth NO. | 701-11 |

| Address in Japan |

〒811-4321 福岡県 遠賀郡遠賀町虫生津1445-1 |

| Address in English |

1445-1 MUSYOZU,ONGA-CHO,ONGA-GUN,FUKUOKA,811-4321,JAPAN |

| Website | http://wks-co.com |

| taka@wks-co.com | |

| Phone number in Japanese |

093-291-1778 |

| FAX in Japanese | 093-291-2728 |

| Phone number in English |

+81-93-291-1778 |

| FAX in English | +81-93-291-2728 |

| PR message | Suggestions and of the mold cost to 1 / 10-1 / 50 "innovation! Original miniature mold production system"! In this inter-mold, and bring the desktop compact injection molding machine, do the actual molding demonstration. |

| The Main Item |

Injection molding micro lens array

|

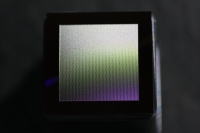

| The name of Item[1] | Microlens array |

| Details[1] | This product was processed in 5-axis nanomachines is, 20,273 pieces spherical meter in the 20mm × 20mm, lens one shape radius R0.15mm, depth 0.03mm, as the accuracy, PV0.8μm, and Ra25nm, excellent it is a micro-lens array. This built-in ultra-small precision molds of nested, so that injection molding, you can be ultra-low price, the mold cost to 1 / 10-1 / 50. This ultra-compact mold production system is now, as prototype and small lot molded article is in the middle optics-related and biotechnology-related research, has been utilized.

|

| The name of Item[2] | Microneedle array |

| Details[2] | The micro-needle array that was subjected to microfabrication in 3-axis machining centers, there are 400 of the needle to 20mm × 20mm in, the shape of the needle, a conical shape, bottom φ0.45mm, height 0.65mm. This product is intended to be used as a master mold in the production of the needle patches, accuracy is very important. In addition, a technique that is applicable to drug the future, peace of mind, can be used safely, and because it is also possible to reduce the burden of patients, it is one that is expected to develop future of technology.

|

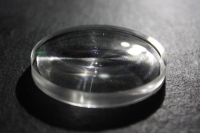

| The name of Item[3] | Direct carving acrylic resin lens |

| Details[3] | The direct cutting lens is subjected to direct cutting an acrylic resin in 5-axis nanomachines and processed. Surface roughness of the lens of 15mm × 10mm you have and Ra5nm, a very good processing accuracy. The direct cutting resin lenses, primarily as prototype in the middle research, which is often used, has achieved a very low cost. Conventional method for manufacturing a prototype lens is said to be only a few no need only to produce a lens mold, such as metal, incorporated into large-scale manufacturing apparatus is manufactured substantially similarly to the method of mass production came. However, by using this direct carving technique, since such large-scale equipment is not required, because it was able to realize a short delivery time and very low cost, it becomes possible to able to consult the number of researchers, research I think that you have help you promote. By all means, it is proposed that it should Dakere had help you this technology research.

|

| The name of Item[4] | Direct carving acrylic resin Fresnel lens |

| Details[4] | The direct cutting lens is subjected to direct cutting an acrylic resin in 5-axis nanomachines and processed. surface roughness of the lens of φ50mm you have and Ra5nm, a very good processing accuracy. The direct cutting resin lenses, primarily as prototype in the middle research, which is often used, has achieved a very low cost. Conventional method for manufacturing a prototype lens is said to be only a few no need only to produce a lens mold, such as metal, incorporated into large-scale manufacturing apparatus is manufactured substantially similarly to the method of mass production came. However, by using this direct carving of technology, since such large-scale equipment is no longer needed, it can be realized the quick delivery and very low price.

|

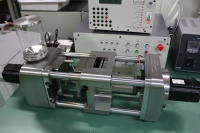

| The name of Item[5] | Tabletop compact injection molding machine |

| Details[5] | It is an injection molding machine of a full-length 60cm. With a small mold, which is incorporated, by using, we will achieve ultra-low price, super fast delivery.

|

| The name of Item[6] | Ultra-small mold |

| Details[6] | 12cm × is telescopically ultra-small mold of 8cm. By use with desktop compact injection molding machine, we realize ultra-short delivery time, the ultra-low price.

|

| The name of Item[7] | Aspherical lens mold |

| Details[7] | Is processed in 5-axis nanomachines, various non-spherical shapes. In particular surface accuracy, we are processing with a commitment.

|

| The name of Item[8] | φ50mm microlens array |

| Details[8] | Material φ50mm micro lens array of STAVAX.

|

| The name of Item[9] | φ30μm tangsten carbide thin pin |

| Details[9] | φ30μm, it is cemented carbide pin of a collection of best of our company of technology of length 20mm.

|

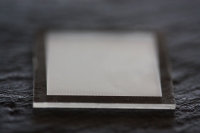

| The name of Item[10] | Tangsten carbide of squares and stones |

| Details[10] | Tangsten carbide cross-cut is subjected to ultra-precision surface grinding, achieve a surface roughness Ra15nm. The stones are manufactured in cemented carbide and ceramic. Superb, in making contest those of 2014, was awarded the Grand Prize. In the future, repeated daily vegetarian, and is willing to smitten manufacture better products. In the future, the more of your guidance and encouragement, Thank you very much.

|

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Materials Mold Components Formed Products Others H. PRESS FORMING MACHINES Servo Press J. PLASTIC FORMING MACHINES Injection Molding Machines N. PARTS PROCESSING TECHNOLOGY Cutting Processing Grinding Processing Plastic Processing Precision Processing |