Top > Exhibitors&Exhibit Items > Exhibitor/Exhibits Search

Exhibitor Detail

| Exhibitor name in Japanese |

福田交易株式会社 |

|---|---|

| Exhibitor name in English |

Fukuda Corporation |

| Booth NO. | 1153 |

| Address in Japan |

〒104-0044 東京都 中央区明石町11-2 |

| Address in English |

11-2, Akashicho, Chuo-ku, 104-0044 Tokyo JAPAN |

| Website | http://www.fukudaco.co.jp |

| eigyou@fukudaco.co.jp | |

| Phone number in Japanese |

03-5565-6811 |

| FAX in Japanese | 03-5565-6816 |

| PR message | We will present the most advanced technology form European machanical parts for machine-tools specialized in precision processing and die molding, including the high torque milling spindle and other products for aerospace parts manufacturing. We will release highly functional components for EDM machine as new products. We not only offer products, but provide technical service. |

| The Main Item |

Precision mechanical parts for machine-tool.

|

| The name of Item[1] | FKD SYSTEM/ Machining test software (reference exhibit) |

| Details[1] | Five-axis machine is structure that rotary axis overlap on top of the straight axis. Normally, the motion and assembly error of each axis will be cumulative. Therefore in order to increase the motion accuracy, it is important to correctly the compensation by understanding the cause of the cumulative errors resulting from the motion error and assembling of each axis, Measurement and compensation software "FKD system" is easy to understand to anyone the motion error, which is measured by R-TEST. It is possible to display the geometric error, you can easily create a compensation value. Also in conjunction with the "FKD system", we will propose a "Machining software (reference exhibit)". Through the use of the software, it is possible to check the actual Machining effect of the compensation. If there are enough not to reduce the error (is expected influence of the heat and so on) by "FKD System", it is possible to understand the cause by the machining test.

|

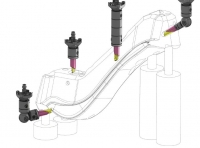

| The name of Item[2] | Novator AB Orbital Drilling Unit |

| Details[2] | Novator AB is located in Stockholm , Sweaden. It keeps being adopted as Boeing, Airbus and Bombardier etc , focusing on airplane industry with original technology specialized in drilling process . The orbital drilling unit make to improve the precision of the drilling process to CFRP/Titanium/Aluminium. [The product feature] * It's possible to make the chip smaller for interrupted cutting, and it's capable of removal. * It's possible also to stop the damage which gives it to a work material because a chip is small. * It's possible to improve the tool life due to interrupted cutting. * The load to the thrust direction achieves 1/10 more than conventional drill processing, and they're able to restrain a burr and delamination by it's effect. * It's possible to improve the processing enviromental , because of the vacuum organization in drilling process .

|

| Details[3] |

|

| Details[4] |

|

| Details[5] |

|

| Details[6] |

|

| Details[7] |

|

| The name of Item[8] | HYPROSTATIK Hydrostatic Guide shoe |

| Details[8] | New Hydrostatic gide shoe is desinged with hydrostatic pressure supply pocket and PM-flow controller compactly. You can complete a guide face in the other side, just load the unit and build the most suitable hydrostatic guide system. A high stiffness hydrostatic guide will complete by built-in PM-flow controller. Wear free, unlimited life, no vibration by rollling elements, excellent damping, no friction at slow move and no stick slip effect.

|

| The name of Item[9] | GMN Labyrinth Seal Type CF |

| Details[9] | Newly designed Non-Contact labyrinth seal, "Type CF" are specifically designed for spindle bearings and offer the highest efficiency with absolutely leak tightness within a minimized space of 6mm width only. The labyrinth design is a combination of gaps in axial and radial direction in five steps. The axial gaps are shielding while the radial gaps are providing back transport. A catching groove improves the sealing efficiancy-even without any shaft rotation.

|

| The name of Item[10] | FCS SYSTEM-Clamping system of Work piece and EDM |

| Details[10] | Optimize the number of combinations for all types of clamping parts that makes it easy to arrange any kind of work piece in a short period of time. The Guideline software allows you to calculate the set it up during the CAD phase. Don’t use your original designed special jig, you must have FCS system. [Product Features] 1.Clamping system of Work piece ●5 free faces of the work piece Unrestricted acces to the five faces of the work piece. ●Flexibility Optimaize the number of combinations for all types of parts. ●System stiffness is high, it is especially suitable for large work. piece. ●Reduce of setup time Is easy to clamp method, we can significantly reduce the setup time and the cycle time. 2.Clamping system of EDM FCS EDM series has become a usable system with the standard FCS system. By using the EDM system, from the processing of the electrode, it becomes possible to realize in one chuck to EDM.

|

| Category of Exhibit Items |

C. MACHINE ACCESSORY Work Holding Devices Accessories & Attachments Others D. CUTTING TOOLS Cemented Carbide Tools K. PRECISION MEASURING, OPTICAL MEASURING MACHINES & INSTRUMENTS Measuring Machines and Instruments Others N. PARTS PROCESSING TECHNOLOGY Cutting Processing Others |