Top > Exhibitors&Exhibit Items > Exhibitor/Exhibits Search

Exhibitor Detail

| Exhibitor name in Japanese |

ボーラー・ウッデホルム株式会社 |

|---|---|

| Exhibitor name in English |

BOHLER-UDDEHOLM KK |

| Booth NO. | 721 |

| Address in Japan |

〒102-0085 東京都 千代田区六番町2-8 番町Mビル |

| Address in English |

Bancho M Building 2-8 Rokubancho, Chiyoda-Ku Tokyo 102-0085 Japan |

| Website | http://www.bohler-uddeholm.jp |

| info@bohler-uddeholm.jp | |

| Phone number in Japanese |

03-5226-3771 |

| FAX in Japanese | 03-5226-6110 |

| Phone number in English |

+81-3-5226-3771 |

| FAX in English | +81-3-5226-6110 |

| PR message | BOHLER-UDDEHOLM KK marked its beginning in 1953 as a sales company for special steels including various types of tool steels in Japan. Its manufacturing mills, Uddeholm (Sweden) and Bohler (Austria) are world-renowned for their innovation and quality for well over a few centuries. Bohler-Uddeholm continues to play a pivotal role as the global market leader within the Tooling Industry and the high end Special Steel application field. |

| The Main Item |

Powder Metallurgy steels (Uddeholm SuperClean, Bohler Microclean),Plastic Mould steels (Stavax ESR)

|

| Details[1] | EDRO400 is a remelted 400 series martensitic stainless steel supplied prehardened to approximately 40 HRC. EDRO400's chemical composition, melting and refining practice and heat treatment, establish physicaland mechanical properties designed to prove: - Homogineity - Superior polished surface finish - Improved corrosion resistance - Reduced mold maintenance costs - Dimension stability - Uniform and consistent hardness - Safe and simple weld repair Applications -Plastic injection mold (insert/ cavities) -Exrusion tooling -Rubber molds -Construction parts

|

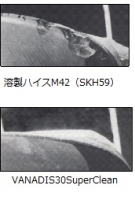

| The name of Item[2] | SUPERCLEAN/MICROCLEAN VANADIS 30/60 SUPERCLEAN、S290/S390 MICROCLEAN |

| Details[2] | Superclean/ Microclean powder metallugy is the steel production process to achieve the very clean steel. The high cleanliness contributes to improve the chipping resistance which is required for the cutting tools. SuperClean ia a trade mark of UDDEHOLM and Microcleasn is a trade mark of BÖHLER, respectively. Properties These steels are high speed steel conaining cobult. Achieved hardness is more than 65HRC and good compressive atrength and wear resistance improve the cutting tool life compared with AISI M42 and other Co-added high speed steels. Applications Cutting tool -Endmill, hob cutter, broach, drill, tap, industrial knife Cold work tool -punch, die, work roll

|

| The name of Item[3] | STAVAX ESR |

| Details[3] | Uddeholm Stavax ESR is a premium grade stainless tool steel with the following properties; - good corrosion resistance - excellent polishability - good wear resistance - good machinability - good stability in hardening Lower mould maintenance costs The surface of cavity impressions retain their original finish over extended runnning perioss. Moulds stores or operated in humid conditions require no special protection. Lower production costs Since water cooling channels are unaffected by corrosion, heat transfer characteristics, and therefore cooling efficiency, are constant throughout the mold life, ensuring conbsitent cycle times. These benefits, couples with the high wear resistance of Uddeholm Stavax ESR, offer the moulder low -maintenance, long-life mouldss for the greatest overall moulding economy. Uddeholm Stavax ESR is produced using the Electro Slag Remelting (ESR) technique, resulting in a very low inclusion content.

|

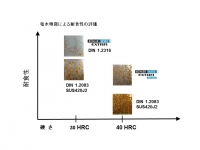

| The name of Item[4] | M303/ M303 HH (high hard) |

| Details[4] | Böhler M303 is a corrosion resistant martensitic stainless steel suppled prehardened condition. The delivered hardness is about 30HRC for M303 and about 40HRC for M303 HH which has better wear resistance. M303/M303 HH are characterized by: -Superior corrosion resistance -Good polishability -Good ductility and toughness -High level of dimension stability -Uniform and consistent hardness Applications -Injection moulds requiring the high corrosion resisitance -Moulds for PVC fitings, rubber moulds, extrusion tools, construction parts

|

| The name of Item[5] | Uddeholm NIMAX |

| Details[5] | Uddeholm Nimax is a low carbon plastic mould steel delivered at a hardness of about 40HRC. Uddeholm Nimax is characterized by the following: -Excellent machinability -Very good welding properties -Good polishing and texturing properties -Good resistance against indentations -High impact and fracture toughness -Consistent properties through large sections The excellent machinability and easy weldability, no prehardening or post treatment necessary, reduce the manufacturing time and make the maintenance much easier. The high hardness in combinaion with good resistance to indentations and a minimum risk for unexpected failures, leading to a safer mould and a prolonged tool life. Applications Moulds for plastic injections Packaging industry -Containers of different types Automotive industry -Larger interior parts -Reflectors Appliances -Panels and handles Holder material for forging and die casting dies Holder material for cutting tools Hot runner manifolds Structural components

|

| The name of Item[6] | Böhler M340 ISOPLAST |

| Details[6] | Böhler M340 ISOPLAST is a high performance stainless plastic mold steel including nitrogen. Böhler M340 ISOPLAST is characterized by: - Good wear resistance - Good corrosion resistance - Good polishability - Good etchability - Good toughness/ ductility - Good machinability Applications - Mould for plastics containing adrasive and corrosive fillers - Mould used at elevated processing temperatures - Mould for highest precision parts

|

| The name of Item[7] | Stailess concept |

| Details[7] | Plastic materials are a part of our everyday life. Car parts, mobile phones, computer chassis are all manufactured by moulds. Rust problem are common with moulds - surface that need to be repolished, cooling channels that have to be redrilled. Choosing the right producut within our Stainless Concept will minimize these problem and contribute to: - increased mold quality - increased productivity - improved end-product finish and quality - reduced maintenance costs |

| Category of Exhibit Items |

A. MOLDS, MOLD MATERIALS Molds Mold Materials Mold Components C. MACHINE ACCESSORY Tool Holders N. PARTS PROCESSING TECHNOLOGY Tooling, Steel Materials |