ABOUT THE SHOW

Exhibitor Search

Exhibitor Detail

| Exhibitor name |

マーポス株式会社

Marposs Kabushiki kaisha

|

|---|---|

| Booth NO. | 6A-522 |

| Address |

〒143-0025 東京都 大田区南馬込5-34-1 マーポスビル Marposs Bldg. 5-34-1, Minamimagome Otha-ku, Tokyo 143-0025 |

| Website | http://www.marposs.co.jp |

| sales_engineering@jp.marposs.com | |

| Phone number | +81-3-3772-8375 |

| FAX | +81-3-3772-5960 |

| PR message | BRANKAMP Press Process Monitoring Syatem, ARTIS Machine Process Monitoring System, VTS High Precision Visual Tool Setter, WRS Radio Frequency Probing System, VOS Visual Optical Probing System, WRP45/60P High Precision Piezoelectric Technology, ML75P Laser Tool Setter and other products displayed. |

| The Main Item |

On Machine Measuring System, Machine Process Monitoring System

|

| The name of Item[1] | BRANKAMP X7 |

| Details[1] | BRANKAMP X7 with AI (Artificial Intelligence) is a high end process monitoring system mainly used on press machines for tool protection and for product quality control. X7 monitor the signal from piezoelectric sensor that measures the force, vibration or distortion of each process/station and of each stroke. X7 system can be easily installed on a various types of machines, parts formers, progressive presses, transfer presses etc. If X7 detects an abnormal signal due for example to a force overload or a scrap mark (slug rise), or a crack on the tool, a stop signal will be sent to the machine control immediately or a warning will be displayed. Furthermore it is possible to choose optimum monitoring method automatically. X7 can monitor up to 24 sensors and innovative monitoring functions are available like - Quattomatic (Double envelope curve), - Systomatic (Average of envelope curves), - Optimizer plus (Automatic envelope width adjustment), - Time machine (Curve history before error).

|

| The name of Item[2] | BRANKAMP X3 |

| Details[2] | BRANKAMP X3 is a process monitoring system mainly used on press machines for tool protection and for product quality control. X3 monitor the signal from piezoelectric sensor that measures the force, vibration or distortion of each process/station and of each stroke. X3 system can be easily installed on various types of machines, ball headers, parts formers, thread rollers, progressive presses, transfer presses, etc. If X3 detects an abnormal signal due for example to a force overload or a scrap mark (slug rise) or a crack on the tool etc., a stop signal will be sent to the machine control immediately or a warning will be displayed. X3 can monitor up to 6 sensors and perform in real time and for each sensor signal the following monitoring operations: Maximum force - Envelope curve (Upper and lower threshold for the complete process) – Trend (Trend of maximum force). With X3 machine and tools are protected from crashes, their life are extended and machine efficiency are increased.

|

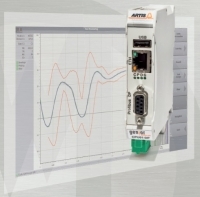

| The name of Item[3] | ARTIS CMS |

| Details[3] | ARTIS CMS (Control Machine Security) is a machine protection system for machine tools, robotic and handling systems. Collisions between different moving parts of a machine generally lead to high repair costs and long downtimes. Sensor installed on a machine spindle detects dynamically increasing forces and sends a stop signal to the machine drives immediately. Strength of the collision to be detected can be set by the operator using a threshold. Your benefit of CMS: ・CMS reduces the response time to 1/1000 compare to the machine operator work (CMS response time: nearly 1[ms]). ・Immediate detection of rapid force changes. ・Log last 100 events with time and date. ・Easy retrofit – regardless of machine type and control. Rely on the experience of more than 10,000 installations on machines, handling systems and robots. CMS contribute to improving your machine efficiency, extending machine life, decreasing machine maintenance cost, allow multiple machine operation without operator.

|

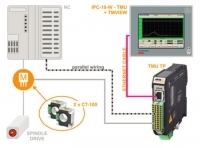

| The name of Item[4] | ARTIS CTM system |

| Details[4] | CTM system safeguards machine tool and optimizes process and tool life thanks to in-process monitoring of metal cutting. Operator can set parameters and limits for each process by themselves so that respond flexibly to almost all applications. This system can connect our various sensors like Acceleration sensor, AE sensor, Hall sensor, Force sensor, Torque sensor, Flow sensor and can get digital axis load from machine by sensor less if it’s established communication with machine via field bus such as Profibus. It’s also possible to save data in order to confirm the cutting data later as traceability.

|

| The name of Item[5] | ARTIS GENIOR MODULAR system |

| Details[5] | GENIOR MODULAR(GEM)system safeguards machine tool and optimizes process and tool life thanks to in-process monitoring of metal cutting. Because of parameters and thresholds are set automatically in mass production processing, the setting by operator is not required. This system can connect our various sensors like Acceleration sensor, AE sensor, Hall sensor, Force sensor, Torque sensor, Flow sensor and can get digital axis load data from machine by sensor less if it’s established communication with machine via field bus such as Profibus.

|

| Details[6] | TMU(Tool Monitoring Unit) is an entry level monitoring system by spindle power. It is determined to detect tool breakage, missing and tool wear during simple metal cutting process. Due to its hard-wire I/O interface, TMU is not dependent on the type of NC. TMU system can handle up to 63 different cycles and provides 3 monitoring strategies. The software requires Microsoft Windows OS PC and the PC can be removed after setting the parameters.

|

| The name of Item[7] | VOS MULTI-CHANNEL OPTICAL TRANSMISSION PART PROBING SYSTEM |

| Details[7] | Optical transmission protocols comprise wide noise immunity. Wide transmission angle 110°and long transmission range up to 6 m. It is ideal system for machine tools such as 3-axis milling machine and machining center, NC lathe, turning center etc. VOS supplies various probe bodies (microswitch type, tripod type, piezo type) according to the measurement application. Modular type transmitter and extensions adapt to various measurement conditions such as deep hole measurement. When 2 VOI receivers used, it is possible to use 2 transmitters same time. This function is effective for 2 axis spindle head machine etc.

|

| The name of Item[8] | WRS RADIO TRANSMISSION PART PROBING SYSTEM |

| Details[8] | This system is Long transmission range up to 15 m, and not require Line of Site, Ideal for medium and large machine tools. (3-axis, 5-axis milling machine and machining center, NC lathe, turning center, multi task machine etc.) WRS has acquired certification for frequency 2.4 GHz band of radio communication system in many countries of the world. Radio system are composed by 79 channeles and 4 sub-channels, It is possible to use up to 316 touch probes in the communication area. Low power consumption design realized long time continuous 900/1500 hours (WRP40/WRP60), with general lithium battery.

|

| The name of Item[9] | Mida Laser P CONTACTLESS LASER TOOL CHECKING SYSTEM |

| Details[9] | It is a contactless laser measurement system for tool's diameter and length. Laser measurement provides improved machining accuracy, by perform measurement and correction as same as during machining. Mida Laser P provides improvement productivity from appropriate tool management, Save waste scrap and additional work. Measurement environment is protected by 2 mechanical functions and machine internal process. - Mechanical shutter protects the lens from the harsh environment inside the processing machine. - Air tunnel barrier protects the laser light for remove false signals cause by coolant droplets and chips. For various tool's sizes and applications, Mida Laser P has some of types and size. - Integral type is precision measurement unit for small diameter tools. - Modular type is measurement unit for large diameter tools.

|

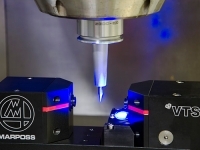

| The name of Item[10] | VTS Visual Tool Setter |

| Details[10] | VTS system is a contactless measurement system and enables highly accurate measurement. It is effective for precision tool's inspection that quality important than production volume. VTS system possible measure wide variety of tool shape and precision tool, that cause error in case of laser measure system. In addition, VTS system can completely automate the tool measurement necessary for fine processing machine. This measurement include tool length, static or dynamic tool diameter, runout, radius of curvature, and temperature drift correction of machine axis, at one positioning cycle. In additon, It is possible to calcuate rotation speed with synchronizing shutter time. VTS system can measure the tool diameter and the tool length more accurately than the laser measure sytem. and, It is possible to directly measure tool diameter with repeatability of 0.2 μm (range) , 0.2 μm (6σ).

|

| Category of Exhibit Items |

H. PRESS FORMING MACHINES Others I. ACCESSORIES & TOOLS FOR PRESS FORMING MACHINES Safety Device K. PRECISION MEASURING, OPTICAL MEASURING MACHINES & INSTRUMENTS Measuring Machines and Instruments Forming & Surface Roughness Measuring Machines Automatic Precision Measuring Machines & Instruments Others |